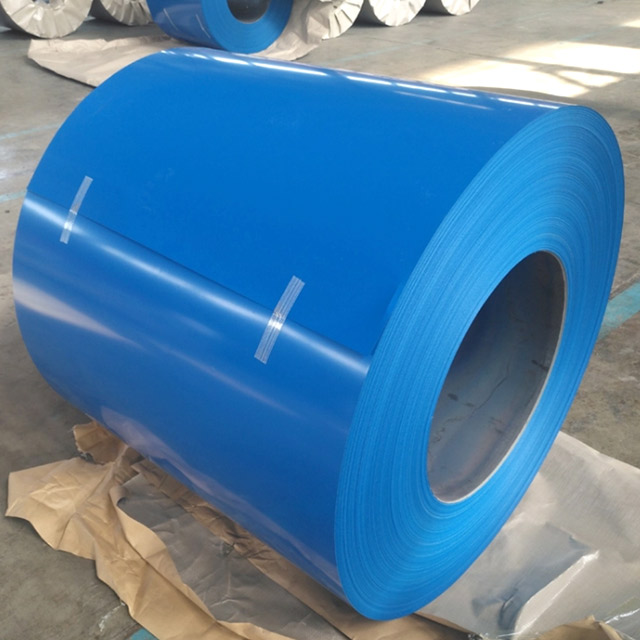

Color steel, known as color-coated steel, is a plate with an organic coating. Widely used in construction, household appliances, and transport industries, the construction field accounts for the largest proportion—particularly large public buildings, public factories, mobile homes, and integrated housing walls and roofs.

The substrates of color-coated steel are cold-rolled, hot-dip galvanized substrates and electro-galvanized substrates. Categories are divided into veneer, color steel composite panels, floor slabs, etc. The types of coatings can be classified as polyester, silicone-modified polyester, vinylidene fluoride, and plastisol. The surface state of color-coated steel can be divided into, coated plate, embossed plate, and printed plate.

Color coated steel parameters

| Definition | Steel with organic coating |

| Use | Construction, Home appliances, Transport(With construction accounting for the largest share, followed by appliances and, to a lesser extent, transport) |

| Substrate | Cold rolled substrates, hot-dip galvanized substrates, electro-galvanized substrates |

| Form | Veneer, colour steel composite panels, floor slabs, etc. |

| Coating type | Polyesters, silicone-modified polyesters, vinylidene fluoride and plastisols |

| Surface state classification | Coated, embossed and printed boards |

Color coated steel production process

The production process of color-coated steel is quite mature. In the production process, the steel plate undergoes steps such as surface degreasing, phosphating, and complexion treatment. Continuous application of organic coatings, and baked and cooled.

This production process not only ensures the excellent performance of color steel but also makes it possible to control it cost-effectively. Further, promotes the application of color steel in various fields. The coating structure has two coatings and one baking, two coatings, and two baking, etc. The maintenance-free service life of 10-30 years depending on the ambient atmosphere.

Advantages of color coated steel

Color steel, i.e. color-coated steel sheets, is a steel with an organic coating. Because of its good corrosion resistance, bright colors, beautiful appearance, easy processing, and shaping, as well as having the original strength of the steel plate and other advantages. It is widely used in many fields such as construction, home appliances, and transport. The advantages of color steel are mainly in the following aspects:

1.Excellent corrosion resistance

The organic coating on the surface of colored steel can effectively resist corrosion and prolong its service life, especially in humid, acidic, and alkaline environments.

2. Good decorative

Color steel is rich in color. It can be customized with different colors according to the demand, meanwhile, the surface is glossy and has a good decorative effect.

3. Convenient processing and shaping

Color steel has good plasticity and toughness, and can be cut, welded, bent, and other processing techniques, which is convenient for making various structures and components.

4. High strength and lightweight

Color steel inherits the original strength of steel plate, while the weight is relatively light, which is easy to transport and install.

5. Environmental protection and energy saving

The waste materials in the process of color steel production can be recycled, which can reduce environmental pollution, while its good thermal insulation performance helps to save energy and reduce consumption.

In summary, color steel has obvious advantages in terms of corrosion resistance, decorativeness, ease of processing and forming, etc. When choosing to use color steel, it needs to be weighed and considered according to specific needs and scenes.

What is color coated steel used for?

From small doors and windows, home accessories, and bags, to large building facades, trains and aircraft have his shadow. Because it has many of the above advantages, it has such a wide range of applications. For the construction, electrical appliances, transport, and other fields to provide an efficient solution. The following is a detailed description of his application industry:

1.Architecture

The construction of exterior wall panels, roof panels, interior wall panels, etc. is not only good-looking, but also corrosion-resistant and very durable. Due to the special treatment of the surface, the color is stable under sunlight and not easy to fade, which greatly improves the aesthetics.

2.Home Appliances

Production of housings and exterior panels for refrigerators, washing machines and air-conditioning appliance. Color coated steel has high hardness, not easy to scratch and good corrosion resistance, which can keep the appearance of home appliances beautiful and novel for a long time, and enhance the market competitiveness of products.

3.Vehicle Manufacturing

Manufacture of automobiles, trains, aeroplanes,body shell, doors, roof, etc. Resists scratches, smudges, and fingerprints so that extended use.

| Appliance | Substrates | Examples of applications |

| Architecture | Hot-dip galvanized steel and hot-dip gavalume steel | Roofs, Walls, Doors of industrial, Commercial buildings, Steel-framed factories, Airports,Warehouses, Freezers, Etc. |

| Home appliance | Electro-galvanized/ cold plate | Refrigerators, Furniture, Freezers, Large air-conditioning systems. |

| Transportation | Electro-galvanized/ cold plate | Oil sump, Automotive interior parts |

Characteristics Of Colored Steel

-Oxygen index: (OI) 32.0 (National Fire Products Quality Inspection Station)

-Thermal insulation: core material thermal conductivity: λ<=0.023-0.041w/mk

-Light weight: 10-14 kg/m2, equivalent to 1/30 of a brick wall

-High strength: resistance to bending and compression, can be used as ceiling enclosure plate load-bearing, general housing without beams and columns.

-Bright color: no surface decoration is required, and the anti-corrosion layer of colored galvanized steel can be maintained for 10-25 years.

-Flexible and quick installation: construction cycle can be shortened by more than 40%

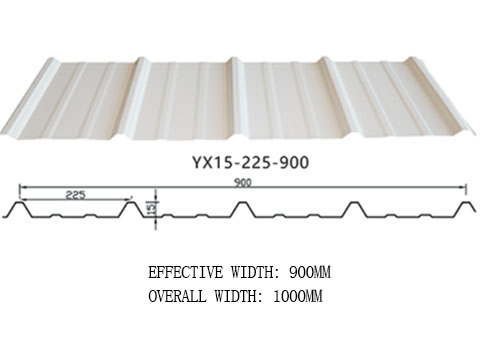

Specification type and fire rating of color steel

Type:Types 470, 600, 760, 820, 840, 900, 950, 870, 980, 1000, 1150, 1200, etc.

Fire rating: Class A B1, B2, B3 (non-combustible, flame-retardant, flame-retardant, flammable)

Conclude

With its unique advantages and wide range of applications, color coated steel has become an indispensable material for modern construction and decoration industries. WanZhi products not only have excellent performance, but also have novel design and beautiful appearance, which can meet the needs of different customers, we strictly control the quality, customer demand oriented, after-sales service all-round, if you are looking for high quality color steel products, why don’t you choose WanZhi, and we will be wholeheartedly at your service. Color and Scheme can be customized~