Cold-rolled steel and hot-rolled steel are the two most common steels. The biggest difference between the two is the production process.

Cold-rolled steel and hot-rolled steel have their own advantages and disadvantages and are suitable for different scenarios. This article will explain the difference between cold-rolled steel and hot-rolled steel to help you choose the right steel for your project.

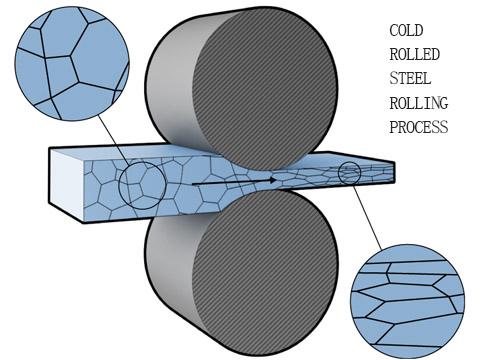

Cold Rolled Steel

Cold rolled steel production process

Cold rolled steel is hot rolled steel that has been heat treated at room temperature, which is then further rolled, cooled and annealed at room temperature.

Cold rolled steel is rolled multiple times to achieve more accurate dimensions and better surface quality.

Pickling → Cold rolling → Annealing → Oiling → Surface treatment → Inspection → Packaging and storage

Cold rolled steel appearance

- The surface is flat and smooth, with high gloss and no scaly residue.

- The surface color is silvery white and evenly smooth.

- The edges are neat and smooth, without burrs or irregular shapes.

Advantages and disadvantages of cold rolled steel

Advantages of cold rolled steel

- High dimensional accuracy, cold rolled steel is rolled at room temperature, and will not shrink due to temperature difference after forming.

- High surface quality, cold rolled steel has high surface finish and flatness, and no scaly residue.

- The strength and hardness of cold rolled steel are relatively high, and the strength is 20% higher than that of hot rolled steel.

Disadvantages of cold rolled steel

- The cost of cold rolling is high, because rolling at room temperature requires a larger rolling power.

- The price of cold rolled steel is more expensive than hot rolled steel, and the price is about 1.2 times that of hot rolled steel.

- When rolled at room temperature, the toughness of cold rolled steel is relatively poor.

- Cold rolled steel is prone to internal stress, which will affect the performance of steel.

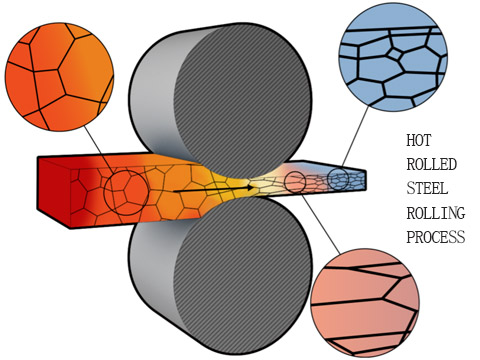

Hot Rolled Steel

Hot rolled steel production process

Hot rolled steel is formed by continuously rolling steel billets at high temperatures, usually above 1000℃ (higher than the recrystallization temperature of steel); it is then cooled.

Raw material preparation → Pretreatment → Rough rolling → Intermediate rolling → Finishing rolling → Cooling → Cutting and leveling → Packaging and storage

Hot rolled steel appearance

- The surface is relatively rough, due to the scaly residue left after high temperature cooling.

- The surface gloss is low, and the surface color is uneven dark and rusty.

- There are certain burrs or irregular shapes on the edges.

Advantages and disadvantages of hot rolled steel

Advantages of hot rolled steel

- Low production cost and high production efficiency.

- There is almost no internal stress, and the heat treatment process of hot rolled steel will eliminate internal stress.

- Good mechanical properties and easier processing. Since hot rolled steel is rolled at high temperature, plasticity, toughness, tensile strength, etc. will be improved.

Disadvantages of hot rolled steel

- The surface quality is relatively poor, the surface of hot-rolled steel is rough, and there may be defects such as scale and rust.

- The dimensional accuracy is low. After hot-rolled steel is rolled at high temperature, there is a cooling process. After cooling, the hot-rolled steel will shrink unevenly, resulting in the dimensional accuracy of the finished product being not as high as that of cold-rolled steel.

Cold rolled steel applications

Cold rolled steel is suitable for small-scale production and high precision requirements, and is usually used to produce thin plates, wires, strips, bars, etc.

- Aerospace structural parts

- Automobile manufacturing

- Home appliances

- Metal furniture structure

- Mechanical parts

Hot rolled steel applications

Hot rolled steel is suitable for mass production and industrial applications, and is usually used to produce thick plates and steel sections.

- Agricultural equipment

- Automotive parts

- Bridges

- Steel structural components

- Pressure vessels

- Metal buildings

We provide you with high quality cold rolled steel and hot rolled steel products at the most competitive prices. Please contact us for details.

Conclusion

When choosing cold rolled steel or hot rolled steel for your project, it is necessary to understand the difference between the two. The performance and application of these two types of steel are very different. Through this article, you should have a certain grasp of the difference between cold rolled steel and hot rolled steel.

Wanzhi Steel Group is a professional steel manufacturer. If you have purchasing needs, you are welcome to contact us at any time.

Why choose Wanzhi Steel

- We have rich industry experience and have more than 13 years of production experience.

- We have complete inspection equipment and a 500㎡ quality inspection center.

- We have more than 30 engineers and technicians.