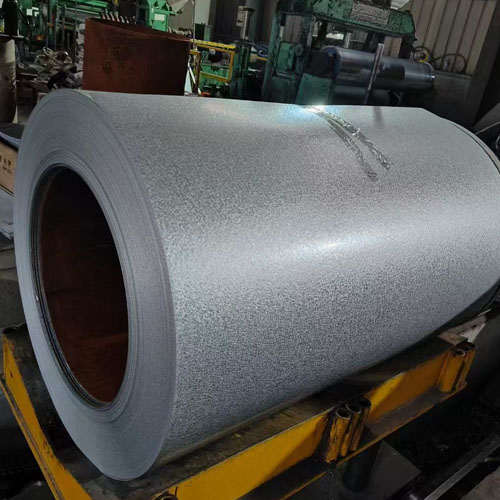

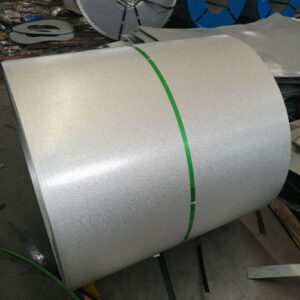

S250GD Z275

S250GD Z275 galvanized steel has high strength, excellent corrosion resistance (thick zinc layer), easy processing, and is more economical than stainless steel (3 times cheaper than stainless steel). If you have any questions about the product, please feel free to contact us.

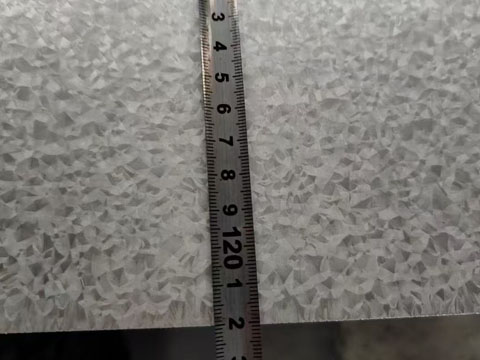

Thickness: 0.12mm – 6mm

Width: 600mm – 1500mm

Length: 2000mm – 6000mm or cut as per customer’s requirements

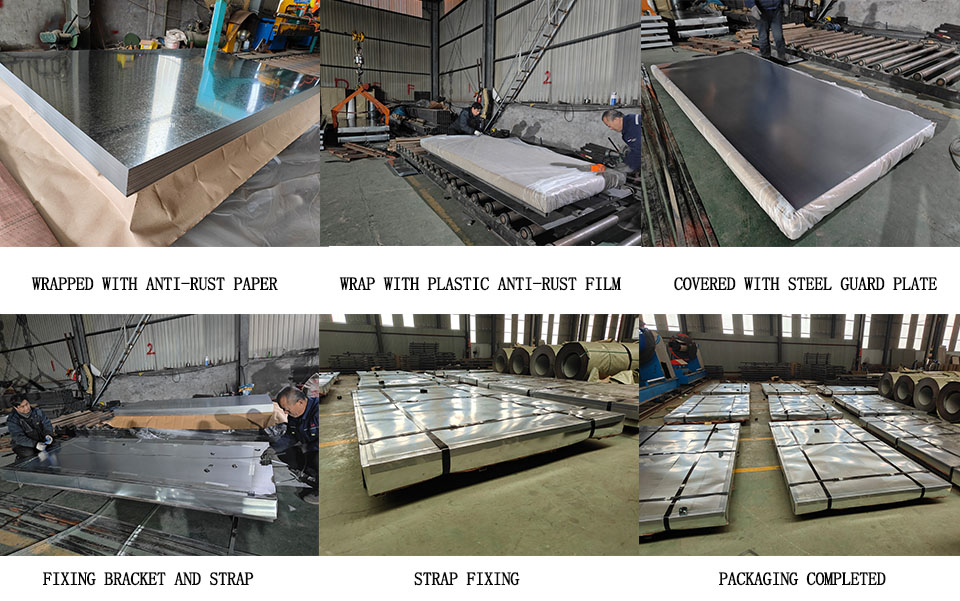

Ensure product quality and transportation

S250GD+Z275 is a hot-dip galvanized structural steel product, where “S” stands for structural steel, “250” means the minimum yield strength of the steel is 250MPa, and “GD” means hot-dip galvanizing. The “Z” in “Z275” stands for pure zinc coating, and 275 means the unit area mass of the zinc coating is 275g/m².

Z275 is a thicker pure zinc coating with excellent corrosion resistance and the strength of the substrate S250GD, so it is widely used.

S250GD Z275 GI Steel Specification

| Product Name | S250GD Z275 |

| Thickness | 0.12mm – 6mm |

| Width | 600mm – 1500mm |

| Length | 2000mm – 6000mm or cut as per customer’s requirements |

| Galvanizing amount | 275g/㎡ |

| Product type | Coil, sheet, strip, etc |

| Standard | EN 10346 |

| Surface treatment | Oiling, passivation, oil-free, pre-painting, etc. |

| Processing services | Slitting, cutting, bending, profiling, punching, embossing, etc. |

| Yield strength | ≥250MPa |

| Tensile strength | 330-450MPa |

| Elongation (A80mm) | ≥18% |

| MOQ | 10 tons |

| Packaging | Standard export package or as per your requirements |

S250GD Z275 Galvanized Steel Application

- Building structure: used to manufacture factory columns, beams, purlins; building roof panels, floor slabs, etc.

- Automobile field: commonly used in automobile body frames, chassis beams and other key load-bearing parts.

- Energy facilities: used in the manufacture of photovoltaic racks, substation frames, transformer shells, transmission tower components, etc.

- Transportation: highway sound barriers, truck beams, bridge guardrails, subway ventilation ducts, etc.

- Machinery Manufacturing: for manufacturing tractor chassis, harvester frames, heavy-duty shelves, etc.

S250GD+Z275 Service Life

The lifespan of S250GD Z275 galvanized steel is different for different usage scenarios.

| Application scenarios | Main causes of corrosion | Service life |

| Exterior walls of urban buildings | Low corrosion, no salt mist or acidic gas | 35-40 years |

| Steel structures of industrial plants (inland) | Medium corrosion environment, mild SO₂ pollution | 25-30 years |

| Roofs of coastal commercial buildings | High corrosion, salt mist, humidity | 15-20 years |

| Agricultural greenhouse frames | Occasional condensation, no salt mist or acidic gas | 35+ years |

| Highway sound barriers | Exhaust gas + snow-melting salt | 18-22 years |

| Subway ventilation ducts | Humidity + condensed water | 22 years or so |

| Photovoltaic brackets (deserts) | Sand erosion + UV aging | 20-25 years |

Ways to increase service life

- Use chromate passivation.

- Choose a more weather-resistant coating – PVDF.

- Apply zinc paint every few years (3-5).

Corrosion Resistance Comparison Between Z275 and AZ50

| Test items | Z275 (pure zinc) | AZ50 (aluminum zinc alloy) |

| Salt spray test | 1000 hours (red rust) | 2000 hours (red rust) |

| Wet heat test | 1500 hours | 3000 hours |

| Applicable scenarios | Industrial atmosphere | High humidity/coastal environment |

Packaging

Why Choose Us?

- High product quality: we use high quality raw materials and advanced production equipment, no leakage plating and zinc tumor on the surface, uniform zinc layer and stable performance.

- High company reputation: we have passed many certifications such as ISO 9001, ISO 14001, etc. We have successfully exported to more than 120 countries, and our products and after-sales service are recognized by customers.

- Rich types of products: We have many kinds of processing equipments to produce and supply galvanized steel sheet, corrugated galvanized steel sheet, pre-painted galvanized steel, galvanized steel pipe, galvanized wire and other products.

Wanzhi Steel is a professional manufacturer of galvanized steel products with two hot-dip galvanizing production lines and one electro-galvanizing production line, the factory is located in Binzhou City, Shandong Province, China, with zinc coating ranging from Z30 – Z275, with sufficient production capacity, fast delivery, and big discounts for large quantity orders, if you need galvanized steel products, please feel free to contact us.

You may be interested: SGCC GI Steel | DC01 Galvanized Steel | S350GD+Z