Laminated PETG Film Metal Sheets

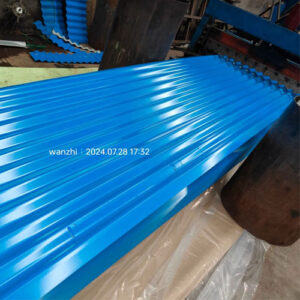

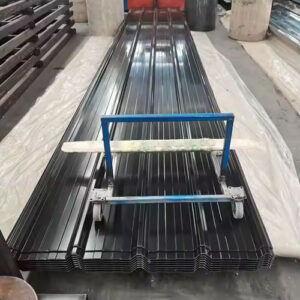

Our laminated PETG film metal sheets come in solid colors, gradient hues, diverse patterns, and textures, with comprehensive specifications and extended service life.

- Substrate thickness: 0.2 – 2mm

- Width: ≤1500mm

- Product type: Coil/Sheet/Strip Coil

Ensure product quality and transportation

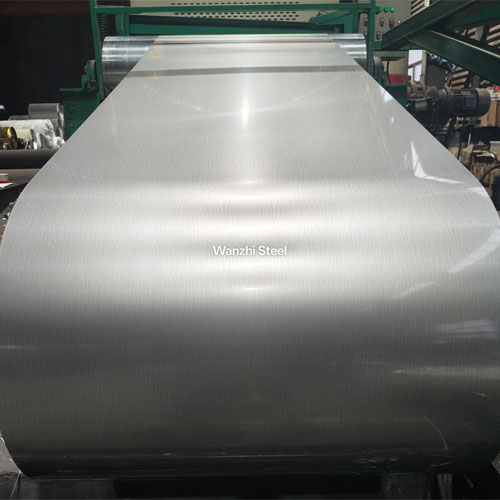

Laminated PETG film metal sheet rolls, also known as PETG-VCM metal rolls, are a new functional material created by bonding PETG film to a metal substrate through an eco-friendly lamination process. Supplied in continuous roll form, they combine high strength with excellent decorative properties and are widely used in the home appliance industry.

Specifications

| Product Name | Laminated PETG Film Metal Coil Sheet |

| Substrate type | Cold-rolled steel, galvanized steel, aluminized zinc steel, aluminum alloy, etc. |

| Substrate thickness | 0.2 – 2mm |

| Width | ≤1500mm |

| PETG film thickness | 12-50μm |

| Roll weight | 1- 8 tons |

| Product type | Coil/Sheet/Strip Coil |

| Color | Various solid colors (RAL color chart), gradient colors, custom colors. |

| Surface finish | High gloss, matte, wood grain, brushed metal, crackle, stone texture, and other various patterns and textures. |

| MOQ | 10 tons |

| Packaging | Standard export packaging (plastic film, moisture-proof paper, and galvanized iron sheet) |

Product Detail Showcase

Production Process

- Metal Substrate: Undergoes the process of “degreasing → water washing → chemical conversion (phosphating/chromium-free passivation) → drying.”

- PETG Film: Surface energy is increased through high-voltage discharge, raising it above the surface tension of the adhesive to achieve full wetting and spreading of the adhesive.

- Hot-melt Laminating: The PETG film carries an inherent hot-melt adhesive layer. During hot-pressing, the adhesive melts and bonds with the metal substrate under heat, forming a robust union upon cooling.

Performance Advantages of Laminated PETG Film Metal Sheets

- Superior Surface Properties: Scratch-resistant, chemically durable, with precisely controllable gloss levels. Functional films (antibacterial, antistatic) enable specialized metal coil applications.

- Superior Formability: PETG film’s high flexibility allows it to deform in tandem with the metal substrate, accommodating complex shapes during processing. It resists cracking during bending and enables continuous processing with high efficiency.

- Extended Service Life: Resistant to various chemical corrosions, with strong weather resistance and scratch resistance, resulting in a longer lifespan than pre-painted metal coils.

Applications of Laminated PETG Film Metal Sheets

- Home Appliance Industry (Core Applications): Refrigerators/freezers, washing machines, dishwashers, various kitchen appliances/small appliances.

- High-End Interior Paneling: Cabinet doors, interior partitions, commercial space walls; integrated ceilings and curtain wall linings for kitchens and bathrooms.

- Packaging & Specialty Containers: Premium food cans, gift boxes, medical device housings, laboratory furniture, etc.

Why Choose Us

- Trusted Supplier: Our products hold multiple certifications including ISO 9001, ISO 14001, and CE, and we are recognized as a Trusted Supplier by the China Certification Association.

- Strong Resource Coordination: With nearly 15 years in the industry, we maintain deep partnerships with relevant suppliers, enabling rapid production of laminated metal coil products.

- Superior Product Quality: Our in-house testing center subjects every product to rigorous inspections covering mechanical properties, chemical composition, corrosion resistance, and more. We also support third-party testing.

If you require laminated metal coils or steel for home appliances, feel free to contact us anytime for detailed product information.