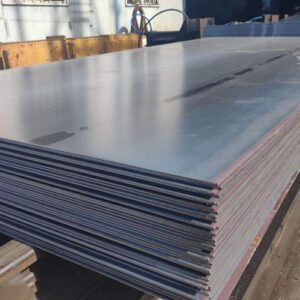

Hot Rolled Steel Strip

We can supply hot-rolled steel strips of various specifications with high product quality and short delivery cycle. We can also provide services such as slitting and cut-to-length.

Thickness: 1.2 – 20MM

Width: ≤600mm

Material: Q195, Q235, Q345B, SPHC, A572, S195, S235JR, S275JR, etc.

tag: Steel Strip

Ensure product quality and transportation

Hot rolled steel strip is directly produced or cut from hot rolled steel coils through longitudinal shearing equipment. The production process is simple and efficient. If you need hot rolled steel strips and hot rolled steel coils, please contact us.

Specifications

| Product name | Hot Rolled Steel Strip |

| Thickness | 1.2 – 20MM |

| Width | ≤600mm |

| Material | Q195, Q235, Q345B, SPHC, A572, S195, S235JR, S275JR, etc. |

| Standard | GB,EN,JIS,ASTM,DIN |

| Processing Services | Slitting, cutting, profiling, etc. |

| Coil inner diameter | 508mm or 610mm |

| Coil outer diameter | 900-2200mm |

| Coil weight | 8 tons – 40 tons |

| MOQ | 25 tons |

| Package | Standard Export Package or According to your requirements |

Advantages of Hot Rolled Steel Strips

- Low cost: simple production process, 20%-30% lower energy consumption than cold rolling, lower cost than cold rolling, and significant benefits of large-scale production.

- High production efficiency: continuous rolling, fast speed, annual production capacity of a single line can reach millions of tons, and short delivery cycle.

- Good mechanical properties: high strength, can withstand heavy loads; good plasticity and toughness, not easy to crack during processing.

- Processing advantages: good hot processing performance, can be directly welded and cut without annealing.

Application of Hot Rolled Steel Strip

- Construction field: bridges, factory frames, high-rise building supports, floor slabs, concrete reinforcement, railway pads, guardrail columns, port crane tracks, etc.

- Automobile transportation field: automobile frames, chassis, wheels, etc.; truck beams, frame longitudinal beams, etc.; subway chassis, high-speed rail carriage skeletons, etc.

- Energy engineering: oil/gas pipelines, wind power towers; substation brackets, transmission tower bodies, etc.

- Heavy machinery: excavator tracks, crane booms; agricultural machinery plowshares, rotary tillers; mine steel frames, conveyor belt rollers, etc.

- Marine ships: cargo ship bottom plates, container ship steel plates; port crane booms, conveyor belt brackets, etc.

Hot-rolled Steel Strip vs. cold-rolled Steel Strip

| Comparison items | Hot-rolled steel strip | Cold-rolled steel strip |

| Production process | High temperature rolling: Heating → Rough rolling → Finish rolling → Coiling | Room temperature rolling: pickling → cold rolling → annealing → finishing |

| Performance | Low yield strength, good plasticity and weldability. | High strength, but poor toughness and weldability. |

| Surface quality | Rough, with iron oxide scale, low dimensional accuracy. | Smooth, no oxide scale, high dimensional accuracy. |

| Production efficiency | Continuous rolling, high production efficiency. | Multiple rolling + annealing, low efficiency. |

| Cost | Lower production cost than cold rolling. | High cost. |

For more differences, please read: https://wanzhi-steel.com/cold-rolled-steel-vs-hot-rolled-steel/

Why Choose Us?

- 14+ years of export experience, ISO 9001, ISO 14001 certified enterprise, serving more than 1200+ projects.

- Using high-quality raw materials, advanced production equipment, high production efficiency, sufficient production capacity, and complete specifications.

- In order to ensure that the products meet customer requirements, the products are strictly tested and support third-party testing.

Wanzhi Steel Factory is located in Shandong, close to Qingdao Port. Under the premise of ensuring quality, we provide you with the most competitive prices. In addition to hot-rolled steel coils, we also supply cold-rolled steel coils, GI coils, GL coils, color-coated steel coils, etc. If you have any related steel needs, please contact us.