DX52D Galvanized Steel Coil

DX52D is a grade that complies with European standard EN 10346, and DX52D+Z is a steel that combines processability and corrosion resistance, with its core feature being stamping formability.

Thickness: 0.13mm – 6.0mm

Width: 600mm – 1500mm

Zinc Layer Weight: Z30 – Z275g/㎡

Ensure product quality and transportation

Specification

| Product Name | DX52D Galvanized Steel Coil |

| Thickness | 0.13mm – 6.0mm |

| Width | 600mm – 1500mm |

| Zinc Layer Weight | Z30 – Z275g/㎡ |

| Spangle Types | Large Spangle, Regular Spangle, Small Spangle, Zero Spangle |

| Coil Inner Diameter | 508mm (20″) or 610mm (24″) |

| Coil Weight | 3 – 10 tons/coil |

| Standard | EN 10346 |

| Surface Treatment | Chromated, Chromium-Free, Oiled, Non-Oiled |

| Processing Services | Cutting, Slitting, Embossing, Punching, Profiling, Pre-Painting, etc. |

| Yield Strength | 140 – 300 MPa |

| Tensile Strength | 270 – 420 MPa |

| Elongation (A80) | ≥ 26% |

| MOQ | 10 tons |

| Packaging | Standard export package or as per your requirements |

DX52D Galvanized Steel Coil Advantages

- Excellent Formability: High elongation (≥26%) and excellent plasticity allow it to withstand complex deep drawing, bending, and stretching without cracking, meeting complex shape requirements.

- Strong Rust Protection: The zinc layer on the surface provides corrosion protection and strong corrosion resistance. The zinc layer weight (Z20-Z275g/㎡) can be adjusted to suit different corrosion environments.

- High-Quality Surface: The substrate is flat and the zinc layer is uniform (zero spangle surface), providing an ideal substrate for subsequent spraying and painting.

- High Cost-Effective: Combining durability and ease of processing, it eliminates the need for complex corrosion treatment, meets most stamping requirements, and is competitively priced.

DX52D Galvanized Steel Applications

| Applications | Application Scenarios | Advantages |

| Automotive Manufacturing | Frame supports, door inner panels, fuel tanks, chassis guards | Easy to stamp and bend, the zinc coating resists corrosion from moisture and dust during driving. |

| Home Appliance Manufacturing | Refrigerator/washing machine housings, air conditioner outdoor unit housings, microwave oven linings, etc. | Pre-painted (PPGI coil), it offers both aesthetics and corrosion resistance. |

| Construction | Ventilation ducts, ceilings, roof panels, rolling shutters, wall enclosures, lightweight steel structures | Customizable width and thickness to accommodate various building dimensions, and the zinc coating provides extended outdoor service life. |

| Other Applications | Manufacturing of filing cabinets, distribution boxes, storage racks, office furniture, grain silos, and barns | Highly cost-effective and durable. |

Why Choose Us?

- Wide range of specifications: Thickness (0.13-6mm), width (600-1500mm), and surface finishes of regular or zero spangle can be customized to suit different production scenarios.

- Various coatings and product types: We can produce a variety of coated products, including DX52D+Z, DX52D+AZ, and DX52D+ZM, in coils, sheets, and tubes.

- High product quality: We use high-quality raw materials, utilize advanced production processes, and maintain our own testing center and rigorous inspection procedures to ensure our products meet customer requirements.

- Additional advantages: With confidence in our products, we fully support third-party testing and offer free samples.

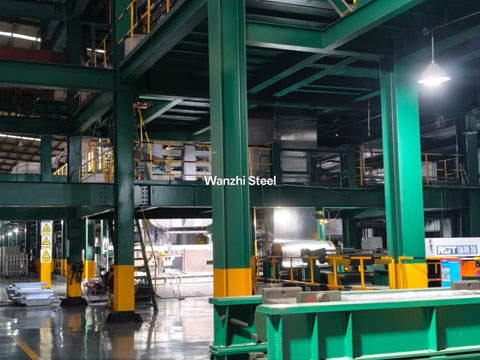

Wanzhi Steel is a manufacturer with extensive production and export experience and holds multiple certifications (including ISO 9001, ISO 14001, ISO 45001, and Trusted Supplier). With high-quality products and reliable delivery capabilities, we help customers obtain cost-effective products. If you have any coated steel product needs, please feel free to contact us.

You may be interested: SGCC GI Steel | Dx51D Z140 | DC01 Galvanized Steel