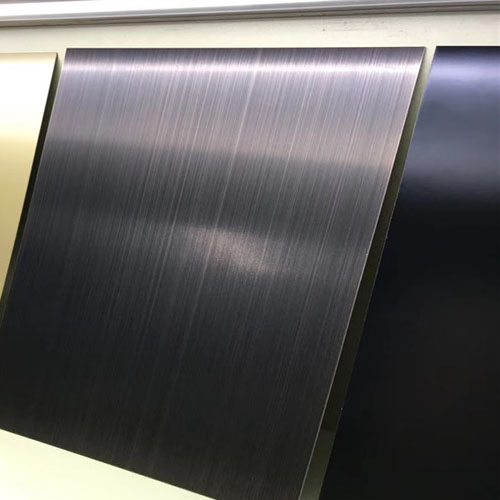

Black Aluminum Sheet

Black aluminum sheet has the characteristics of strong decorative effect and long service life. We can supply you with black aluminum sheets of various specifications. The products are of high quality and favorable price. If you are interested in black aluminum sheet, please contact us.

Thickness: 0.2 – 6mm

Width: 1000mm, 1220mm, 1250mm, 1500mm, 2000mm or customized

Length: Cutting as per requirement

Ensure product quality and transportation

Black aluminum sheet is a commonly used building and decoration material. It is a metal sheet with aluminum alloy as the base material and a black appearance after special treatment on the surface. It has a unique appearance, strong corrosion resistance, wide application and high investment value. If you need any aluminum-related products, please feel free to contact us.

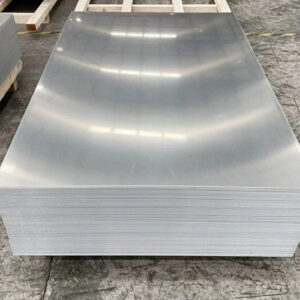

Specifications and Sizes

| Product name | Black Aluminum Sheet |

| Thickness | 0.2 – 6mm |

| Width | 1000mm, 1220mm, 1250mm, 1500mm, 2000mm or customized |

| Length | Cutting as per requirement |

| Common Sizes | 1220×2440mm(4×8), 1500mm×3000mm, 2000mm×3000mm, etc. |

| Grade | 3003, 5052, 5083, 6061, 6063,etc |

| Surface treatment | Matt, glossy, brushed, sandblasted, etc. |

| Processing services | Cutting, bending, welding, profiling, punching, embossing, etc. |

| MOQ | 5 tons |

| Delivery time | 10-20 working days |

| Packing | Standard Export Package or According to your requirements |

Methods and Characteristics of Achieving Black Effect of Aluminum Sheet

| Methods | Production Process | Features | Applicable scenarios |

| Anodizing | Electrolytic oxidation → dyeing → sealing | Metallic texture, wear-resistant, high temperature resistant, high cost | Electronic products, high-end decoration, industrial parts |

| Fluorocarbon spraying (PVDF) | Electrostatic spraying of PVDF fluorocarbon paint → high temperature curing | Super weather-resistant (20 years +), UV/acid and alkali resistant, high price | Building curtain walls, outdoor facilities |

| Polyester spraying (PE) | Electrostatic spraying of polyester paint → curing | High cost performance, various colors, medium weather resistance (5-10 years) | Interior decoration, home appliances, advertising |

| Powder spraying | Electrostatic adsorption of powder coating → high temperature curing | Environmentally friendly, thick coating, scratch-resistant, optional texture | Industrial equipment, furniture, doors and windows |

| Laminating (PVC/PET) | Surface pasting of PVC/PET black film | Low cost, easy to process, poor weather resistance, easy to age | Short-term advertising, interior decoration |

Advantages of Black Aluminum Sheet

Strong decorative effect

- High-grade texture: Black gives the surface of aluminum sheet a high-end and calm visual effect, which can enhance the overall aesthetics and quality when used in modern buildings.

- Strong matching: As a neutral color, black can be matched with a variety of colors and materials, and the design space is broad.

- Surface diversity: The surface of black aluminum sheet can be processed into matte, high gloss, brushed and other effects to meet different design needs.

Performance advantages

- Strong weather resistance: The black coating formed by anodizing and spraying has good weather resistance and chemical resistance.

- Excellent corrosion resistance: Aluminum itself has good corrosion resistance, and with the addition of coating, the corrosion resistance is stronger.

- Easy to process: It can be cut, bent, pressed, punched and other processing operations, which is suitable for customized needs.

- Lightweight and high strength: Aluminum sheet has low density (2.7g/cm³), light weight, and high strength and rigidity.

Environmental protection and economy

- Recyclable: Aluminum is a recyclable metal material with a recycling rate of over 90%.

- Economical: The comprehensive cost of aluminum plates is low. For example, the life of fluorocarbon sprayed aluminum plates can reach more than 20 years, with a long service life and low maintenance cost, which is more economical.

Application of Black Aluminum Sheet

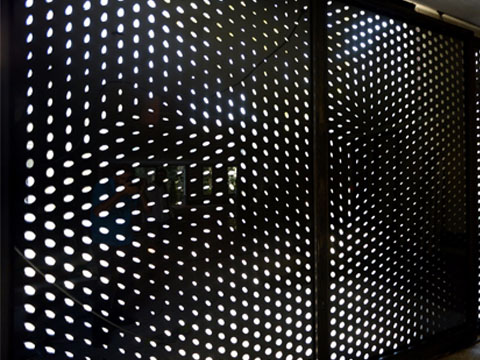

- Architectural decoration: roof materials, curtain walls, wall decoration, ceilings, partitions, canopies, door and window frames.

- Transportation: automobile engine hoods, doors, luggage racks and other parts; high-speed rail/subway interior panels, truck compartments.

- Electronic appliances: electronic equipment radiators, chassis, panels (mainly anodized).

- Advertising signs: display racks, billboards, signboards, light boxes, etc.

- Furniture manufacturing: furniture frames, drawer panels, decorative strips and other parts.

- Industrial equipment: instrument housings, protective covers, etc.

Why Choose Us?

- The products are made of high-quality raw materials and excellent production technology to ensure stable product performance.

- We follow strict testing procedures to test product specifications, performance, appearance, etc., and support third-party testing.

- The black aluminum sheets we supply have a variety of specifications and different surface treatments to meet the needs of different customers.

Wanzhi Black Aluminum Sheet Product Type

- Black Flat Sheet

- Black Corrugated Aluminum Sheet

- Black Perforated Aluminum Sheet

Wanzhi Steel is an ISO 9001:2015 certified experience. With many years of production and export experience, we can develop a perfect solution for your project. If you have any needs, please feel free to contact us.