Stainless Steel Laminate Coil/Sheet

Introduction

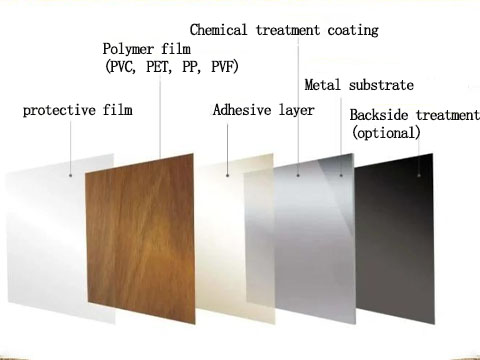

Stainless Steel Laminated Coil/Sheet is a high-performance metal decorative material that combines functionality with aesthetic appeal. Using premium stainless steel coil or sheet as the substrate, advanced lamination technology permanently bonds polymer films such as PVC, PET, or PP to the steel surface.

This process preserves the stainless steel substrate’s exceptional corrosion resistance and structural stability while incorporating the diverse decorative effects of polymer films (such as varied patterns and textures). It finds broad application across multiple sectors including architectural decoration, home appliance manufacturing, and kitchen/bathroom fixtures.

Table of Contents

Specifications of Laminated Metal Sheet

| Product Name | Stainless Steel Laminate Coil/Sheet |

| Materials | 201, 304, 304L, 316, 316L, 309, 310S, 410, 430, 2205, 2507, etc. |

| Stainless Steel Thickness | 0.3mm – 10mm |

| Width | 1000mm, 1219mm, 1250mm, 1500mm, 1800mm, 2000mm, etc. |

| Length | Based on customer requirements. |

| Coil Weight | 3 tons – 10 tons |

| Film Thickness | 0.03mm – 0.1mm |

| Film Type | PVC, PET, PP, PE, etc. |

| MOQ | 5 tons |

| Packing | Wooden pallets, wooden boxes, paper boxes, or as requested |

Stainless Steel Laminating Core Process

The stainless steel laminating process fundamentally employs high-temperature, high-pressure composite technology to achieve material bonding:

- Functional layers made of plastic films such as PET, PC, PE, or PP are placed with stainless steel substrates under specific pressure and temperature conditions. Through physical compression, the film forms a tightly bonded composite structure with the steel surface;

- This process eliminates the need for additional adhesives. Instead, high temperatures soften the film while high pressure reinforces adhesion, ensuring the film layer remains firmly bonded to the substrate. The result is a composite sheet that combines the strength of stainless steel with the properties of the film layer;

- The core function is to enhance the decorative appeal, corrosion resistance, and practical adaptability of the steel while preserving its fundamental properties.

Characteristics of the Laminating Process

- Highly Customizable: Choose decorative films like high-gloss or iridescent finishes, or functional films such as UV-resistant or antimicrobial options, enabling flexible configuration of appearance and performance.

- Strong and Stable Bonding: The high-temperature, high-pressure process ensures the film adheres tightly, resisting edge curling or peeling, and withstands subsequent processing like cutting and bending.

- Eco-Friendly with Premium Texture: Compared to chemical coating processes like baking paint, film coating production is more environmentally friendly. while delivering a smoother, more refined surface texture that elevates tactile quality.

Stainless Steel Laminated Coil Sheet Products Advantages

- Exceptional Stain Resistance and Easy Cleaning: The surface film effectively repels grease, water stains, dust, and other contaminants. A simple wipe restores its pristine finish, reducing maintenance complexity and costs.

- Significantly Enhanced Durability: The film provides additional moisture resistance and UV protection, making the sheet suitable for diverse indoor and outdoor environments while extending its service life.

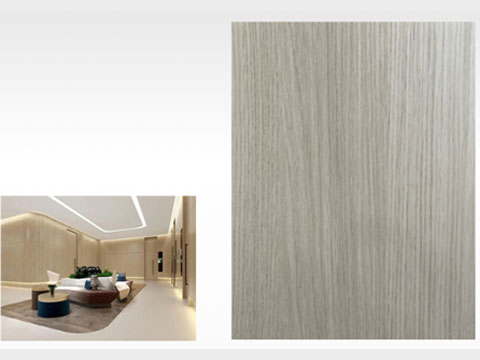

- Versatile Decorative Effects: The manufacturing process supports a wide range of film options in colors and textures (e.g., wood grain, brushed finish, solid colors), catering to diverse aesthetic preferences from modern minimalism to personalized styles and expanding stainless steel’s application scenarios.

Stainless Steel Laminated Coil Sheet Applications

| Application Areas | Application Scenarios | Recommended Film Types |

| Architectural Decoration | Indoor walls/ceilings, elevator interiors, residential wall panels, outdoor advertising light box back panels, balcony railing panels. | Choose PET brushed film/colorful film for indoor use; choose weather-resistant PET film for outdoor use. |

| Home Appliance Manufacturing | Refrigerator side panels/top panels, washing machine housings, air conditioner exterior covers (partial), microwave oven housings, oven side panels, rice cooker top panels, soymilk maker housings. | Choose PET heat-resistant film for high-temperature applications; choose PVC solid color film for ordinary applications. |

| Kitchenware and Bathroom | Cabinet doors, cabinet sides, countertop water retaining strips, bathroom cabinet doors, shower partition frames, sink decorative panels, restaurant kitchen countertops. | Choose PET anti-scratch film/antibacterial film for kitchens; choose PET moisture-proof film for bathrooms. |

| Furniture and Home Furnishings | Wardrobe doors, desk tops, TV cabinet sides; office furniture such as conference table panels, filing cabinet housings, and partition screen panels. | Choose PVC wood-grain film for wood-grain applications; choose PET high-gloss film for offices. |

| Commercial Use | Fast food restaurant wall panels and tea shop countertop panels; Medical facilities: hospital clinic walls and nurse station worktop panels. | Choose PET anti-fouling film for restaurants; choose antibacterial PET film for medical applications. |

| Vehicle Interiors | Subway/high-speed rail carriage interior panels, seat back decorative surfaces, RV interior wall panels, cold chain vehicle interior decorative panels, and ship interiors. | Choose PET impact-resistant film for rail transit applications; choose PE low-temperature-resistant film for cold chain vehicles. |

Related Products

Why Choose Us

- We utilize premium eco-friendly polymer materials such as PVC and PET, capable of reproducing diverse textures including wood grain, stone patterns, and leather finishes.

- Our stainless steel laminate panels come in a full range of specifications, feature diverse film types, and are manufactured using advanced production techniques. They offer stable performance and a long service life.

- With over 14 years of production and export experience, our products have earned praise from customers across multiple countries, accumulating successful exports to over 100 nations.

Wanzhi Optional Films

- By Material: PVC Film, PET Film, PP Film, PE Film.

- By Functional Properties: Textured Film, Anti-Fingerprint Film, Scratch-Resistant Film, Antibacterial Film, Weather-Resistant Film.

- By Appearance and Application: Black & White Film, Laser Film, Bright Blue Film, Custom Printed Film.

If you have any needs regarding laminated metal sheets, please feel free to contact us

Price

Prices vary significantly due to multiple factors, including raw material costs, specifications and dimensions, material grades, lamination processes and film types, purchase quantities, and transportation expenses. For specific pricing details, please refer to our Stainless Steel Coil Price page.

Contact us directly for pricing inquiries. Please provide your detailed requirements, including:

- Base material thickness (e.g., 0.5mm)

- Stainless steel grade (e.g., 304/2B)

- Coating type and thickness (e.g., PVC film, 0.05mm thick)

- Surface finish (e.g., matte white brushed texture)

- Purchase quantity (e.g., 20 tons)

- Destination port/delivery location

Project Solutions

Agricultural Greenhouse

Highway Engineering

Metal Construction Products

- Metal Roofing

- Metal Sandwich Panel

- Metal Carved Panel

- Angle Steel

- Channel Steel

- Expandable Container House

- 40ft Double-Wing Expandable House

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China