Laminated Pearlescent Film Metal Coil

Introduction

Laminated pearlescent film metal coils represent a high-performance composite metal material that combines the corrosion resistance and strength of metal sheets with the decorative appeal and protective properties of pearlescent PVC film. Through advanced coating technology, it achieves a perfect fusion of aesthetics and functionality.

Wanzhi Steel’s laminated pearlescent film metal sheets come in various colors and gloss levels, offering exceptional beauty. They are highly popular in high-end home appliance manufacturing and the construction industry.

Table of Contents

Specifications

| Product Name | Laminated Pearlescent Film Metal Coil Sheet |

| Substrate Thickness | 0.3mm – 1.5mm |

| Width | <1300mm |

| Film Thickness | 25μm – 200μm |

| Film Type | PVC / PET |

| Base Material | Cold-rolled steel, galvanized steel, stainless steel, aluminum |

| Colors | White, gray, red, yellow, brown, and other colors are all acceptable. |

| Processing Services | Laminated steel sheets, slitting, leveling, cut-to-length, and more. |

| MOQ | 5 tons |

| Packaging | Vertical/horizontal packaging for steel coils, conventional export packaging for steel sheets |

Production Process for Laminated Pearlescent Film Metal Coil

- Uncoiling: Smoothly unroll the metal coil to ensure even feeding.

- Pre-treatment: Remove surface impurities through cleaning and degreasing to guarantee bonding quality.

- Chemical Treatment: Apply passivation or phosphating to enhance substrate rust resistance and adhesion.

- Adhesive Coating: Apply environmentally friendly, high-viscosity adhesive uniformly to promote metal-film bonding.

- Curing: Transfer to a curing oven for heat treatment to achieve preliminary adhesive layer solidification.

- PVC Film Laminating: Precisely bond pearlescent film to the metal substrate under high temperature and pressure.

- Protective Film Laminating: Covering the outer surface with a transparent protective film to prevent scratches during transportation and processing.

- Rolling: Winding the composite sheets into rolls for convenient storage and transportation.

- Cutting and Stacking: Cutting to size as required and automatically stacking the sheets for shipment preparation.

Laminated Pearlescent Film Metal Coil Advantages

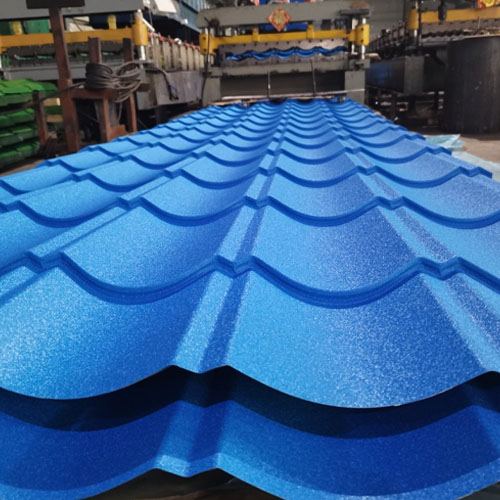

- Diverse Aesthetics: Available in a wide range of pearlescent colors, the pearlescent effect enhances the luxurious texture of metal surfaces.

- Superior Processability: Both the metal substrate and pearlescent film exhibit excellent ductility, enabling deep processing such as forming and punching.

- Superior Corrosion Resistance: Utilizes corrosion-resistant substrates, further enhanced by the pearlescent film’s barrier against external environments.

- Dust, Mold, and Fire Resistance: The dense pearlescent film effectively seals out air and moisture, providing protection against dust and mold.

- Long-Lasting Durability: The pearlescent film exhibits excellent adhesion to the metal substrate, ensuring no delamination or fading for extended service life.

Applications of Laminated Pearlescent Film Metal Sheets

- Home Appliance Manufacturing: Outer casings for refrigerators, freezers, washing machines, microwave ovens, sterilizing cabinets, water heaters, range hoods, soy milk makers, and other appliances.

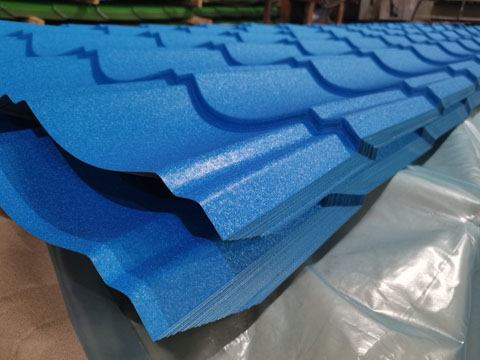

- Building Decoration: Roofing systems, interior ceilings, cabinet door panels, security door finishes, etc.

- Automotive Interiors: Door panels, dashboards, trim strips, etc.

- Furniture Applications: Storage cabinets, writing boards, signage, etc.

Related Products

Why Choose Us

Our Advantages

- Producing laminated pearlescent film metal coils involves complex manufacturing processes and requires comprehensive raw material sourcing capabilities. Our greatest strength lies in supply chain integration.

- We offer not only pearlescent metal coils but also diverse surface textures and patterns (brushed metal, stone-like, wood grain, solid colors, etc.), with strong customization capabilities.

- Certified under ISO 9001, ISO 14001, and other standards, we maintain our own inspection center and fully support third-party testing.

Our Testing Process

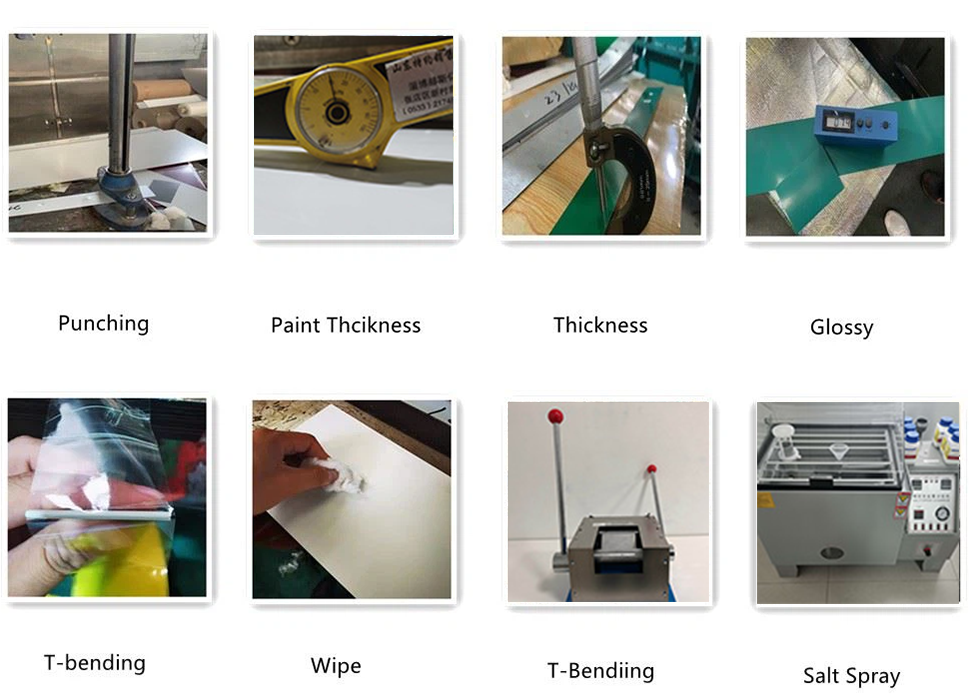

- Formability Testing: Cup test and T-bend test verify processing ductility.

- Mechanical Properties: Impact strength and tensile strength tests evaluate structural durability.

- Environmental Resistance: Salt spray test verifies corrosion resistance; hardness tester assesses surface abrasion resistance.

- Surface Quality: Gloss and roughness tests ensure visual and tactile consistency.

- Adhesion Testing: Evaluates protective film viscosity and laminate bond strength to prevent delamination.

As a professional supplier of laminated metal coil sheets, we possess extensive production and export experience to efficiently deliver high-quality products. If you are interested in premium colored metal coils, please contact us.

Project Solutions

Agricultural Greenhouse

Highway Engineering

Metal Construction Products

- Metal Roofing

- Metal Sandwich Panel

- Metal Carved Panel

- Angle Steel

- Channel Steel

- Expandable Container House

- 40ft Double-Wing Expandable House

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China