Laminated Brushed Film Metal Coil

Introduction

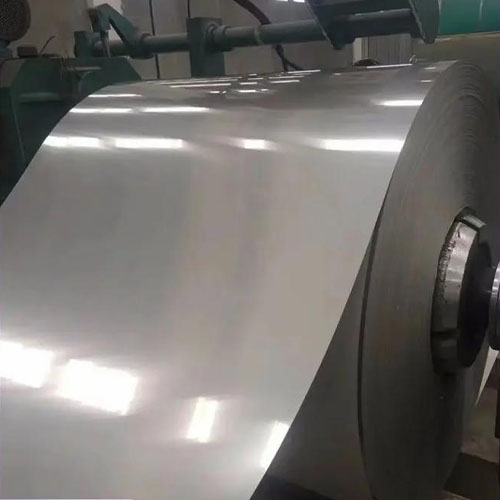

Laminated brushed film metal coil is a high-end metal composite material manufactured through advanced composite processes. Its core structure consists of a “metal substrate + functional film layer + protective system,” achieving stable interlayer bonding via high-temperature pressing or eco-friendly adhesive technology.

Combining the structural strength of the substrate with the decorative and protective properties of the functional film, laminated brushed film metal coils are progressively replacing traditional mechanically brushed steel sheets. They find extensive application in home appliances, construction, and other industries.

Table of Contents

Specifications

| Product Name | Laminated Brushed Film Metal Coil |

| Substrate Thickness | 0.3mm – 1.2mm |

| Width | 600-1250mm (1000mm, 1219mm (48-inch), 1250mm, etc.) |

| Film Thickness | 25μm – 200μm |

| Film Type | PET, PVC, VCM, PETG |

| Substrate | Cold-rolled carbon steel (SPCC, SGCC), GI coil (DX5ID, DX52D, DX53D), aluminum alloy (5052, 6061), stainless steel (304, 316L, 201) |

| Surface Protective Film | PE |

| Metal Coil Inner Diameter | 508mm or 610mm |

| Hardness | ≥ H – 2H |

| T Bend Value | ≤ 2T |

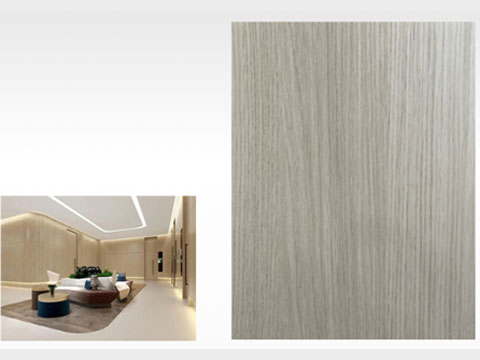

| Brushed Film Textures | Straight, Hairline, Random, Snowflake, Crosshatch, Micro-Abrasion, or Custom Textures |

| Colors | Original Stainless Steel, Champagne Gold, Space Gray, Coffee Gold, Black, etc. |

| Salt spray resistance | ≥500 hours |

| MOQ | 5 tons |

| Packaging | Vertical/horizontal packaging for steel coils, conventional export packaging for steel sheets |

Production Video

Laminated Brushed Film Metal Coil Production Process

- Substrate Pre-treatment: Metal substrates undergo cleaning, degreasing, and phosphating to ensure absolute surface cleanliness.

- Primer Application and Curing: A high-performance primer is applied to the pre-treated metal sheet and cured at high temperature, forming a robust protective and adhesive layer.

- Hot Press Laminating: The brushed-finish film and coated steel sheet are precisely aligned and fed into the laminator. Under specific temperature, pressure, and speed conditions, the hot-melt adhesive layer on the film’s reverse side is activated, firmly bonding with the metal sheet to form an inseparable composite.

- Cooling and Coiling: The composite metal sheet undergoes uniform cooling before being coiled into steel rolls for convenient transportation and subsequent processing.

Laminated Brushed Film Metal Coil Advantages

- Exceptional Stain Resistance and Easy Cleaning: The surface film effectively repels grease, water stains, dust, and other contaminants. A simple wipe restores its pristine finish, reducing maintenance complexity and costs.

- Significantly Enhanced Durability: The film provides additional moisture resistance and UV protection, making the sheet suitable for diverse indoor and outdoor environments while extending its service life.

- Versatile Decorative Effects: The manufacturing process supports a wide range of film options in colors and textures (e.g., wood grain, brushed finish, solid colors), catering to diverse aesthetic preferences from modern minimalism to personalized styles and expanding stainless steel’s application scenarios.

Laminated Brushed Film Metal Coil Applications

- Premium Home Appliances & Kitchen Equipment: Panels and housings for refrigerators, ovens, steamers, range hoods, gas stoves, dishwashers, washing machines, etc.

- Architecture and Interior Decoration: Elevator cabins, door frames, wall cladding panels, counter facings, building curtain walls, storefront signage, etc.

- Other Applications: Medical device enclosures, cleanroom walls, premium office partitions, advertising display boards, high-end display cabinets, smart home control panels, etc.

Related Products

Why Choose Us

- Supply Chain Integrity: With decades of expertise in the steel industry, we integrate upstream and downstream raw materials required for laminated film metal products.

- High Production Efficiency: Precise control over raw materials enables rapid sourcing and swift production of diverse laminated film metal products.

- Stringent Inspection Processes: Our in-house testing center rigorously evaluates mechanical properties, dimensions, corrosion resistance, weather resistance, and supports third-party inspections.

- Integrity-Driven Enterprise: We hold multiple certifications including ISO 9001, ISO 14001, and Trusted Supplier status, earning high customer recognition for our products.

Laminated brushed film metal coils seamlessly blend the strength of metal with the aesthetic durability of surface film. Offering extended service life and controllable costs, these products are ideal for home appliance manufacturers and high-end construction projects. Contact us to learn more.

Project Solutions

Agricultural Greenhouse

Highway Engineering

Metal Construction Products

- Metal Roofing

- Metal Sandwich Panel

- Metal Carved Panel

- Angle Steel

- Channel Steel

- Expandable Container House

- 40ft Double-Wing Expandable House

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China