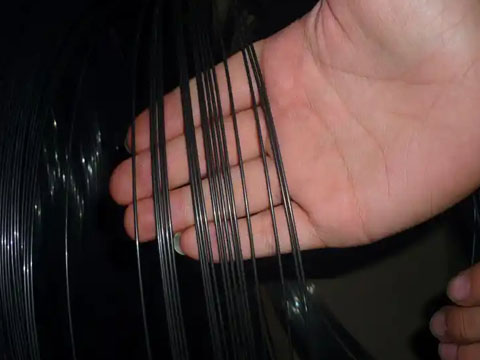

Cold Drawn Wire

Introduction

Cold-drawn steel wire is a metal wire produced through a cold-drawing process. Due to its diverse specifications, wide range of applications, and excellent performance, it is used in construction, agriculture, industry, and household applications.

We are a leading cold-drawn steel wire supplier in China, offering a variety of materials, specifications, and high-quality products, all directly supplied from the source manufacturer.

Table of Contents

Specifications

| Wire Diameter | 1 – 12mm |

| Tensile Strength (MPa) | 550 – 2000+ |

| Material | Q195, Q215, etc. |

| Surface Finish | Bright or galvanized (hot-dip galvanized or electro-galvanized) |

| Minimum Order Quantity | 5 tons |

| Cold-drawn wire gauge | Diameter specification | Weight per meter (kg) |

| 20# | 1.0mm | 0.00617 |

| 18# | 1.2mm | 0.00888 |

| 16# | 1.6mm | 0.0156 |

| 14# | 2.2mm | 0.0302 |

| 12# | 2.8mm | 0.0499 |

| 10# | 3.5mm | 0.0787 |

| 8# | 4.0mm | 0.099 |

| – | 4.1mm | 0.1018 |

| – | 5.0mm | 0.1543 |

| – | 6.0mm | 0.2221 |

| – | 8.0mm | 0.395 |

| – | 10.0mm | 0.617 |

| – | 12.0mm | 0.888 |

Production Process for Cold Drawn Wire

Surface Treatment

Select high-quality carbon wire rod. Then, use a multi-roller machine to peel off surface slag, followed by acid pickling to dissolve residual oxide layers. After rinsing with clean water until no acid residue remains, dry the rod and finally lubricate it.

Core Drawing

Install drawing dies made of materials such as cemented carbide, ensuring the dies are concentric with the drawing axis. Then, use a cold drawing machine clamp to hold the pre-treated material and pull it through the die hole. The machine’s pulling force causes the material to undergo plastic deformation at room temperature.

Multiple Drawings

To achieve target specifications, multiple drawing processes are often performed. Intermediate annealing is incorporated into the drawing process, using a short online heat treatment to eliminate some internal stress and restore plasticity for subsequent processing.

Post-Processing

First, use a multi-roller straightener to correct any bends in the drawn wire, ensuring it meets straightness requirements. Then, perform targeted surface treatments depending on the application, such as annealing, galvanizing for corrosion protection, or straightening and cutting for finishing.

Advantages of Our Cold Drawn Wire

- Made from carefully selected high-quality raw materials and processed using a rigorous cold-drawing process, this product boasts high tensile strength, uniform hardness, and is resistant to deformation and breakage, meeting industry standards.

- A full range of specifications are available, supporting customized production. Multiple surface treatment options, including galvanizing and bare wire, are offered to suit various applications.

- High dimensional accuracy and a smooth, burr-free surface are provided. The galvanized version is weather-resistant, rust-proof, and has a long service life.

- Stable supply and fast delivery are ensured. Pre-sales selection guidance and after-sales tracking service make purchasing and use more worry-free.

Cold Drawn Wire Applications

- In industry, it is used to manufacture automotive steering shafts, gears, springs, bolts, and other components. It can also be used as a raw material for wires and connectors in the electronics and electrical industries.

- In agriculture, it can be used to build greenhouse frames, livestock cages, and to make protective netting and fences for crops, resisting external impacts and resisting deformation.

- As a core building material, cold-drawn wire is used for reinforcing concrete components, as prestressed steel bars, and as wall tie bars. It can also be used to make wire mesh to prevent plaster cracking.

- In large-scale engineering projects, cold-drawn wire can be processed into steel cables and anchor rods, suitable for high-strength load-bearing scenarios such as bridge suspension cables and foundation reinforcement.

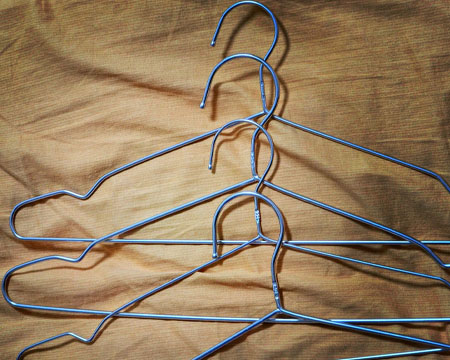

- In everyday life, it can be used to DIY clothes hangers, hooks, and small tools. It can also be used to make security windows and guardrails. Some specifications can also be used for louvered light-adjusting rods and paper clips.

- In horticulture, it can be used to make fences and ties for flower stands. Thinner specifications are suitable for twining vines, while medium-sized specifications can be used to secure flower stands.

Our Recent Project Case

Nearly 100 tons of cold-drawn wire shipped to Spain

- Product procured: Cold-drawn wire

- Cooperation model: From trial orders to long-term, multi-batch, and regular procurement agreements.

- Achievements: After successfully delivering the first batch of 25 tons of product, the customer placed multiple orders, with this single order approaching 100 tons.

- Quantity: 20 rolls of 10mm, 26 rolls of 11mm

- Total weight: Nearly 100 tons

Why Choose Us

- We are a professional cold-drawn steel wire supplier, offering both standard and galvanized cold-drawn wire.

- We provide a variety of materials, specifications, and high-quality products, directly from the manufacturer, ensuring stable supply and fast delivery.

- Our company is certified by ISO 9001, ISO 14001, CE, and other standards, enjoying a high global reputation.

- With over 14 years of export and production experience, we have successfully exported to more than 100 countries.

Wanzhi Steel is a leading steel wire supplier in China, capable of supplying various types of steel wire products to meet the needs of various industries. We warmly welcome customers to visit our factory and can provide free samples. If you have any steel wire purchasing needs, please feel free to contact us.

Related Products

Project Solutions

Agricultural Greenhouse

Highway Engineering

Metal Construction Products

- Metal Roofing

- Metal Sandwich Panel

- Metal Carved Panel

- Angle Steel

- Channel Steel

- Expandable Container House

- 40ft Double-Wing Expandable House

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China