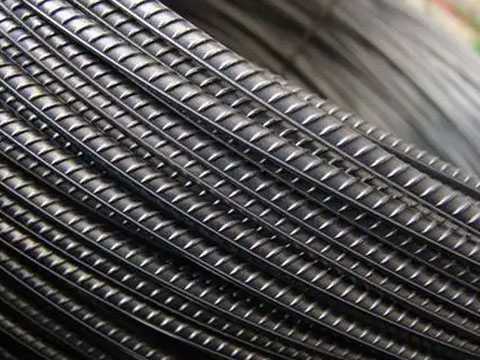

Coiled Rebar

Product Introduction

Generally speaking, rebar is straight, while coiled rebar is coiled, which is easier to transport and store. The coiled rebar we supply has a full range of specifications, high strength, good toughness and ductility. Coiled rebars of different materials and standards can meet the requirements of various projects.

Table of Contents

- Coiled Rebar Specifications

- Application of Coiled Rebar

- Advantages of Coiled Rebar

- Calculation of Coiled Rebar Weight

- Price of Coiled Rebar

- Coiled Rebar vs Ordinary Rebar

- Why Choose Us

Coiled Rebar Specifications

| Product Name | Coiled Rebar |

| Diameter | 6.5mm, 8.0mm, 10m |

| Length | Cut as required |

| Material | Q195, Q215, Q235, Q345, A36, A53, ST37, ST52, Gr40, Gr60, etc |

| Standard | GB, ASTM, BS, EN, etc |

| Technology | Hot Rolled |

| Coil Weight | 2.0 tons or as your required |

| Processing Services | Welding, cutting, bending, etc. |

| MOQ | 10 tons |

| Samples | Free samples |

| Certificates | ISO 9001, ISO 14001, CE, SGS |

| HS Code | 7214100000 |

| Delivery time | 7- 25 working days |

| Packing | Standard export packing or as required |

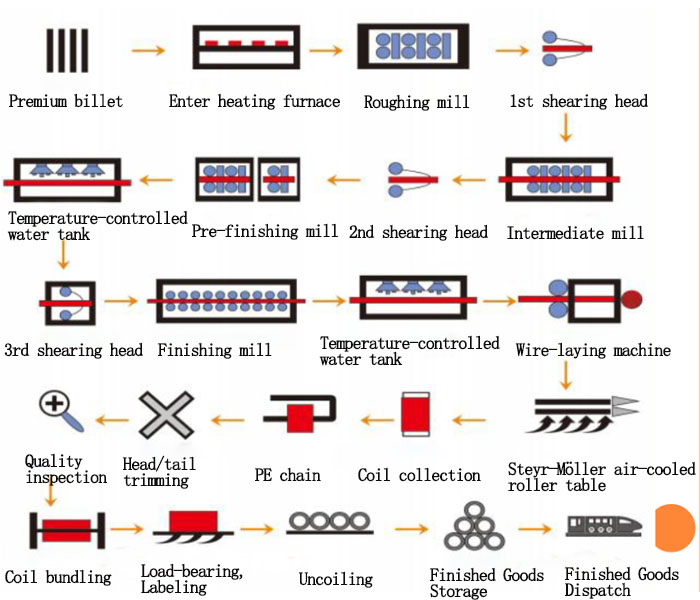

Production Process

Premium billet → Enter heating furnace → Roughing mill → 1st shearing head → Intermediate mill → 2nd shearing head → Pre-finishing mill → Temperature-controlled water tank → 3rd shearing head → Finishing mill → Temperature-controlled water tank → Wire-laying machine → Steyr-Möller air-cooled roller table → Coil collection → PE chain → Head/tail trimming → Quality inspection → Coil bundling → Load-bearing, Labeling → Uncoiling → Finished Product Storage.

Application of Coiled Rebar

- Reinforced concrete structure.

- Foundation treatment and foundation pile production.

- Prefabricated floor slabs, prefabricated wall panels, etc.

- Roadbed reinforcement and slope protection for road engineering projects, etc.

- Bridge structures, underground projects, water conservancy projects, etc.

Advantages of Coiled Rebar

1. Mechanical properties

- High strength.

- Good toughness and ductility.

2. Construction operation

- The length can be cut flexibly to save materials.

- Easy to process and install, shorten construction time.

3. Other advantages

- Easy to store and transport.

- Good stability.

- Low overall cost.

Calculation of Coiled Rebar Weight

Weight calculation formula: W = 0.00617 x D²

- W represents the theoretical weight of coiled rebar per meter, in kg/m.

- D represents the diameter of coiled rebar, in mm.

- 0.00617 is the coefficient obtained by multiplying pi by the steel density of 7850kg/m³ and then dividing by 1000000.

Weight of Coiled Rebar Per Meter of Different Diameters

| Diameter(mm) | Weight(kg/m) | Diameter(mm) | Weight(kg/m) |

| 6 | 0.222 | 14 | 1.21 |

| 6.5 | 0.26 | 16 | 1.58 |

| 8 | 0.395 | 18 | 2 |

| 10 | 0.617 | 20 | 2.47 |

| 12 | 0.888 | 22 | 2.98 |

Price of Coiled Rebar

Depending on factors such as raw material prices, product specifications, and market demand, the price of 1 ton of coiled rebar usually fluctuates between US$500 and US$750.

If you need rebar for your project, please tell us the specifications and quantity you need. We will quickly provide you with the most accurate quotation and provide higher discounts for large-volume orders.

Coiled Rebar vs Ordinary Rebar

| Comparison items | Coiled Rebar | Ordinary Rebar |

| Length | The length is usually long, up to several hundred meters | Straight strips, common lengths are 9 meters and 12 meters |

| Transportation and Storage | It takes up little space, easy to stack and transport | Long, takes up a lot of space, be careful of bending and collision during transportation |

| Construction Convenience | It is easy to cut and bend, suitable for on-site processing | Cutting, welding and other processes may be required during processing, and the construction efficiency is relatively low |

| Mechanical Properties | It usually has high strength and toughness, meeting various mechanical requirements | Strength varies depending on the material and specification, but generally not as flexible as coiled steel bars |

| Processing Difficulty | Straightening requires professional equipment, bending is relatively easy, and can be flexibly processed according to demand | No straightening process is required, cut and bend according to the design size, and large diameter steel bars are difficult to bend |

| Applicable Scenarios | It is suitable for large floors, small components, and parts with high requirements for steel continuity and integrity | Suitable for large structural components, such as high-rise building frame columns, large-span frame beams, etc. |

| Material Utilization rate | Flexible connection methods to reduce material waste | Material waste may occur due to cutting, welding and other processes |

| Connection Method | It can be connected by binding, mechanical connection, etc., with flexible connection methods | Mainly adopts welding, binding and other methods, and the connection method is relatively fixed |

| Material Cost | The production process is complex, the packaging cost is high, and the unit price is usually slightly higher | The price is relatively low |

| Comprehensive Cost | Reduce joints and material waste, and the overall cost may be similar or lower in large projects | If the joint is not handled properly or the material is wasted, the overall cost may increase |

Why Choose Us

- Experienced: 14 years of export experience, complete supply chain, solve your procurement problems.

- Complete specifications: We can supply coils of various specifications and models to meet the needs of different projects.

- High product quality: The supplied coils are high in strength, strong in load-bearing capacity and durable.

- Sufficient inventory: Sufficient production capacity, and a large inventory of commonly used specifications, with sufficient supply.

Wanzhi Steel is an ISO 9001:2015 certified company with rich experience and can provide customers with perfect solutions for projects using rebar. In highway engineering projects, the mastery of the complete supply chain greatly shortens the customer’s procurement time. If you have any needs, please send an email to info02@wanzhisteel.com or contact us online.

Project Solutions

Agricultural Greenhouse

Highway Engineering

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China