PVC-Coated Steel Wire Rope

Introduction

PVC-coated steel wire rope, also known as plastic-coated steel wire rope, is a composite cable manufactured by uniformly coating the surface of high-quality steel wire rope (core) with a layer of polyvinyl chloride (PVC) plastic. It features high strength, high load-bearing capacity, excellent corrosion resistance, weather resistance, and insulation properties.

Wanzhi Steel offers PVC-coated steel wire ropes in diameters ranging from 1.5 to 16 mm. In addition to PVC-coated steel wire ropes, we also supply bare steel wire ropes, galvanized steel wire ropes, wire rope slings, and other products. Please feel free to contact us for any requirements.

Table of Contents

Our Specifications

| Product Name | PVC Coated Steel Wire Rope |

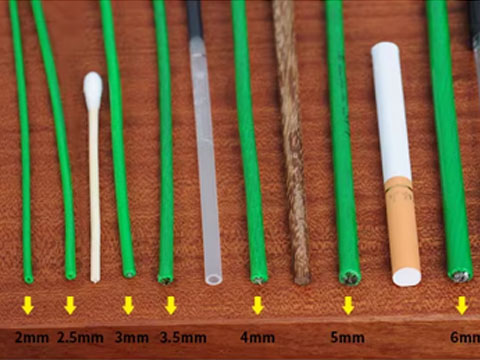

| Diameter | 1.5mm – 15mm |

| Length | Typically supplied in coils/reels, common lengths are 200m, 500m, and 1000m, but custom lengths can be ordered upon request. |

| PVC Thickness | 0.1-0.5mm |

| Internal Material | Galvanized steel wire rope, stainless steel wire rope, smooth steel wire rope |

| Color | White, green, transparent, black, red, etc. Colors can be customized (quantity requirements apply) |

| Tensile Strength | 400-600MPa |

| Performance | Good bending resistance |

| Roll Weight | 5kg, 10kg, 25kg or as per customer requirements |

| MOQ | 5 tons |

| Packaging | Standard export packaging or as required |

Production Process

- Wire Rope Pre-treatment: Standard-compliant galvanized or bare steel wire rope is selected as the core material and undergoes rigorous surface cleaning to ensure removal of oil contamination and oxide layers, providing an optimal adhesion foundation for plastic coating.

- Preheating: The cleaned steel wire rope passes through a preheating device, uniformly raising the temperature of the metal core. This enhances the flowability and adhesion of the subsequent molten plastic coating while preventing defects caused by temperature differences.

- Extrusion Coating: Preheated wire rope passes vertically or horizontally through a cross-head extruder. Under precisely controlled temperature and pressure, molten PVC plastic is uniformly and continuously extruded onto the surface of the wire rope moving at a constant speed.

- Cooling and Setting: The coated wire rope immediately enters segmented cooling tanks. The PVC layer solidifies gradually from the outer layer inward, ensuring a dense structure, uniform roundness, and preventing internal stress.

- Post-Processing and Inspection: Ropes undergo length cutting, end sealing, or spooling as required. Finished products undergo multiple tests including coating thickness measurement, adhesion testing (e.g., cross-hatch adhesion test), electrical insulation testing, corrosion resistance testing, and visual inspection.

Characteristics of PVC-Coated Steel Wire Rope

- Superior Weather and Corrosion Resistance: The PVC coating effectively isolates the rope from air, moisture, salt spray, and weak acid/alkali media. It exhibits outstanding corrosion resistance in atmospheric, mine water, and freshwater environments. Outdoor use requires minimal maintenance, with a service life far exceeding that of standard steel wire ropes.

- Flexibility and Abrasion Resistance: The outer PVC coating enhances rope flexibility, enabling easy bending and forming without coating cracking or fatigue failure from repeated bending. Its smooth surface reduces friction wear, making it suitable for dynamic load applications.

- Excellent Insulation and Shock Absorption: The PVC plastic layer provides reliable electrical insulation protection, suitable for applications requiring insulation. The plastic layer also offers inherent cushioning and shock absorption properties.

- High Strength and Safety: Fully inherits the tensile strength and fatigue resistance of premium steel wire rope cores, ensuring load-bearing safety.

- Outstanding Cost-Effectiveness and Versatility: Compared to PE, TPU, or nylon coatings, PVC reduces costs by 30%-50% while accommodating most application scenarios.

Applications of PVC-Coated Steel Wire Rope

- Lifting, Transportation, and Equipment: Steel wire ropes for port cranes, construction hoists, and meat processing plant lifting equipment—clean and wear-resistant.

- Safety Protection: Safety ropes for aerial work, stadium perimeter netting, construction site safety nets, and mine cage guide ropes.

- Landscaping and Architecture: Guardrail ropes for park greenery, residential perimeter fencing, courtyards, and outdoor sunshade systems; framework for barrier netting.

- Agriculture and Livestock: Greenhouse framework, farm fencing, livestock lead ropes.

- Industrial Fastening and Bundling: Overhead cable traction ropes, pipe bundling and securing, machinery protective netting, shelf tier netting, lightweight equipment securing cables.

- Daily & Civil Use: Clotheslines, pet leashes, pet fencing, craft weaving, and tent guy ropes.

Weight of PVC-Coated Steel Wire Rope

Theoretical Weight Calculation Formula

Theoretical weight of PVC-coated steel wire rope = Weight of steel wire rope core + Weight of PVC coating. The specific formula is as follows:

- Wire rope core weight (kg/m) = 0.00617 × d₁² (where d₁ is core diameter in mm);

- PVC coating weight (kg/m) = 0.0092 × (d₂² – d₁²) (where d₂ is finished diameter in mm, PVC density assumed as 1.4 g/cm³);

- Total finished product weight (kg/m) = 0.00617 × d₁² + 0.0092 × (d₂² – d₁²).

Theoretical Weight Table

| Specifications | Diameter before coating | Diameter with coating thickness | Weight per 100 meters | Meters per kilogram | Reasonable load capacity | Maximum load capacity |

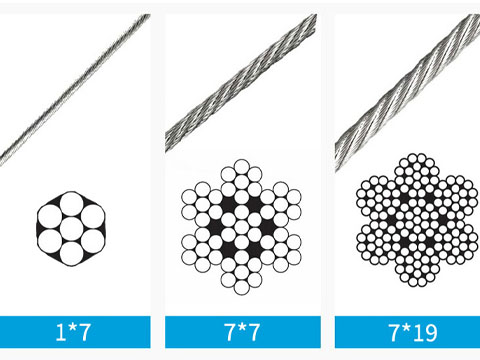

| 1*7 | 0.27mm | 0.38mm | 0.04kg | 2500m | 2.2kg | 9kg |

| 0.3mm | 0.4mm | 0.05kg | 2000m | 2.3kg | 9.3kg | |

| 0.4mm | 0.5mm | 0.09kg | 1111m | 3.9kg | 15.7kg | |

| 0.5mm | 0.6mm | 0.12kg | 833m | 6.4kg | 25.5kg | |

| 7*7 | 0.5mm | 0.6mm | 0.12kg | 833m | 4.4kg | 17.6kg |

| 0.6mm | 0.8mm | 0.2kg | 500m | 6.3kg | 25.3kg | |

| 0.8mm | 1.0mm | 0.33kg | 303m | 11.5kg | 46.1kg | |

| 1.0mm | 1.2mm | 0.49kg | 204m | 15.9kg | 63.7kg | |

| 1.2mm | 1.5mm | 0.72kg | 138m | 30kg | 120kg | |

| 1.5mm | 2.0mm | 1.14kg | 87m | 41.8kg | 167kg | |

| 2.0mm | 3.0mm | 2.3kg | 39m | 73.5kg | 294kg | |

| 3.0mm | 4.0mm | 4.5kg | 22m | 15.9kg | 637kg | |

| 4.0mm | 5.0mm | 7.6kg | 13m | 237.8kg | 951kg | |

| 7*19 | 5.0mm | 6.0mm | 11.5kg | 9m | 367.5kg | 1470kg |

| 6.0mm | 8.0mm | 17.76kg | 5m | 587kg | 2348kg | |

| 8.0mm | 10.0mm | 29.92kg | 3m | 1002kg | 4008kg | |

| 10.0mm | 12.0mm | 45.28kg | 2m | 1420kg | 5688kg | |

| 12.0mm | 14.0mm | 63.84kg | 1.5m | 2045kg | 8100kg |

How to Select the Right PVC-Coated Wire Rope

PVC vs. Other Plastic-Coated Materials

- PVC: Offers the best overall cost-effectiveness with excellent weather resistance, chemical corrosion resistance, and multiple hardness options, suitable for most general applications.

- PE: Superior low-temperature flexibility, water resistance, and flexibility, but may slightly lag behind premium PVC in UV resistance and metal adhesion; typically higher cost.

- TPU: Exceptional abrasion resistance, oil resistance, high elasticity, and low-temperature performance; commonly used in demanding applications like fitness equipment and high-performance tow ropes.

- Nylon: Exceptional toughness, high tensile strength, abrasion resistance, and low elongation. The premium choice for coated ropes, used in high-end sports nets, climbing gear, etc., with the highest cost.

Selection Guidelines

- Define Application: Indoor use: Thin coating (0.4-0.6mm), light colors. Outdoor use: Prioritize thick coating (≥0.8mm), dark UV-resistant colors.

- Cost Control: PVC coating is preferred for general applications. For high-precision or high-load scenarios, pair with PE, TPU, or nylon-coated products to achieve optimal balance between application and cost.

- Performance Requirements: For frequent bending, choose impact-modified PVC material to enhance flexibility. Select fine-core ropes for light loads, medium-core ropes for medium loads, and nylon-coated ropes for heavy-duty applications.

Why Choose Us?

- Extensive Product Range: Beyond PVC-coated steel wire ropes, we offer a comprehensive lineup including bare steel wire ropes, galvanized steel wire ropes, specialty steel wire ropes, and wire rope slings.

- Rigorous Inspection Process: From raw material selection and formulation to final product shipment, every stage undergoes strict quality control to ensure coating adhesion, weather resistance, and mechanical properties meet standards.

- Comprehensive Service Process: Dedicated personnel track every step—from pre-sales technical consultation to order fulfillment, logistics, and after-sales support—providing solutions within 12 hours.

- Trusted Supplier: We hold ISO 9001, CE, SGS, and other certifications, and are recognized as a Trusted Supplier by the Metal Materials Association.

Wanzhi Steel boasts over 15 years of experience in production and export. As a specialized supplier of steel wire products, we offer not only steel wire ropes but also galvanized wire, cold-drawn wire, annealed wire, and more. For any inquiries, please contact us.

Project Solutions

Agricultural Greenhouse

Highway Engineering

Metal Construction Products

- Metal Roofing

- Metal Sandwich Panel

- Metal Carved Panel

- Angle Steel

- Channel Steel

- Expandable Container House

- 40ft Double-Wing Expandable House

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China