Laminated Metal Sheet Products

Introduction

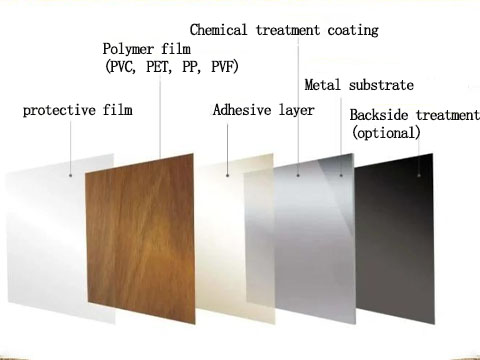

Laminated metal sheets are innovative materials formed by thermally bonding polymer films such as PVC or PET to metal substrates. They combine the corrosion resistance and strength of metal with the decorative properties of polymer films, finding core applications in home appliances, construction, and other sectors.

Wanzhi Steel’s laminated metal sheet products encompass color-coated steel, aluminum, and stainless steel variants. Available in comprehensive specifications, these products deliver stable performance and extended service life. For inquiries, please contact us at any time.

Table of Contents

Specifications of Laminated Metal Sheet

| Product Name | Laminated Metal Sheet |

| Substrate Type | Aluminum alloy, GI steel, GL steel, Stainless Steel |

| Metal Substrate Thickness | 0.2mm – 1.5mm |

| Film Thickness | 0.08mm – 0.30mm (8 wire – 30 wire) |

| Width x Length | Cut to order |

| Gloss | High gloss, semi-matt, full matte |

| Surface Texture | Glossy, matte, suede, frosted, orange peel, brushed, wood grain, stone grain, leather grain, etc. |

| Type | Flat sheet, corrugated sheet |

| MOQ | 5 tons |

| Packing | Wooden pallets, wooden boxes, paper boxes, or as requested |

Laminated Metal Sheet Production Process

- Pre-treatment: Metal substrate surfaces undergo degreasing and cleaning to remove oil and impurities. A chemical conversion process forms a nano-scale protective film to enhance adhesion. The substrate is then water-washed and dried to create a clean, highly reactive base;

- Adhesive coating: High-performance adhesive is uniformly applied using precision roller coating equipment. Coating volume is controlled, and the substrate is preheated to a finger-dry state, establishing a robust bonding bridge;

- Laminating and bonding: Decorative film is precisely aligned with the substrate. A hot press applies high temperature and pressure to expel air and cross-link the adhesive for curing. Cooling and shaping achieve permanent fusion;

- Finally, post-processing and quality inspection: panels undergo 24–72 hours of temperature/humidity-controlled curing to stabilize adhesive properties. They are then cut to shape, fitted with protective film, and pass visual inspection alongside performance tests (adhesion, weather resistance) to ensure final product compliance.

Laminated Metal Sheet Products Advantages

Decorative Advantages

Advanced technology replicates the textures of various natural materials. A wide range of colors and patterns are available, with customization options. Surface gloss levels can also be selected as needed, providing ample design flexibility.

Performance Advantages

Weather-resistant and corrosion-resistant, durable in outdoor and humid environments. Scratch-resistant, easy to clean, chemical-resistant, and fire-retardant. Safe and reliable with a long service life and low maintenance costs.

Processing & Installation Advantages

Supports diverse secondary processing (cutting, slitting, bending, punching, etc.) to accommodate design requirements. Installation employs standardized dry methods, ensuring rapid deployment with minimal external interference and cost savings.

Environmental Advantages

Manufacturing utilizes non-toxic materials, conserves natural resources, and employs recyclable metal substrates, aligning with sustainable development principles.

Laminated Metal Sheet Applications

| Core Application Areas | Specific Applications |

| Architectural Decoration | Commercial building exteriors (e.g., office buildings, hotels, shopping malls); public space interior ceilings/walls (e.g., airport waiting rooms, hospital corridors); residential interior background walls, entryway partitions |

| Home Appliance Manufacturing | Major appliance housings (e.g., refrigerator side panels, washing machine panels, air conditioner exterior covers); small appliance bodies (e.g., oven housings, soymilk maker top panels) |

| Home Furnishings | Custom furniture panels (e.g., cabinet doors, wardrobe side panels, desk tops); functional furniture components (e.g., bathroom cabinet bodies, balcony locker doors) |

| Transportation and Specialty Industries | Automotive interiors (e.g., door trim panels, center console decorative surfaces); marine interiors (e.g., cabin walls, locker panels); industrial plant enclosures (e.g., chemical workshop walls, food factory partitions) |

Related Products

Why Choose Us

- We utilize premium eco-friendly polymer materials such as PVC and PET, capable of reproducing diverse textures including wood grain, stone patterns, and leather finishes.

- Three substrate types—color-coated steel, aluminum alloy, and stainless steel—are available for lamination. Our in-house production lines ensure consistent raw material quality and cost control.

- With over 14 years of production and export experience, our products have earned praise from customers across multiple countries, accumulating successful exports to over 100 nations.

As a professional Chinese supplier of laminated metal sheets, our company holds certifications including ISO 9001, ISO 14001, Trusted Supplier, and Contract-Honoring Enterprise. For inquiries regarding laminated metal sheets, color-coated steel products, stainless steel products, or aluminum products, please contact us for further details.

Project Solutions

Agricultural Greenhouse

Highway Engineering

Metal Construction Products

- Metal Roofing

- Metal Sandwich Panel

- Metal Carved Panel

- Angle Steel

- Channel Steel

- Expandable Container House

- 40ft Double-Wing Expandable House

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China