Galvanized Steel Wire Mesh

Introduction

Galvanized steel wire mesh is a metal grid material featuring a robust protective layer formed on the steel wire surface through galvanization. It finds extensive applications in civil engineering reinforcement, farm animal protection, industrial production filtration, and other fields.

As a galvanized steel wire mesh manufacturer, our minimum order quantity is 5 tons. With versatile applications ranging from large-scale engineering projects to household use, it represents a worthwhile investment.

Table of Contents

Specifications

Galvanized steel wire mesh sheet

| Wire Diameter | 1.0mm – 6.0mm |

| Mesh Size | 12.7mm (1/2″) – 100mm (4″) |

| Frame Dimensions (L x W) | Customization available (2m – 4m) |

| Frame Reinforcement | Frameless / Framed |

| Galvanizing Type | Electrogalvanized / Hot-dip galvanized |

| Zinc Coating Weight | Electrogalvanized: 10-30g/m²; Hot-dip galvanized: ≥60g/m² |

| Surface Treatment | Galvanized plastic coated (PVC/PE) |

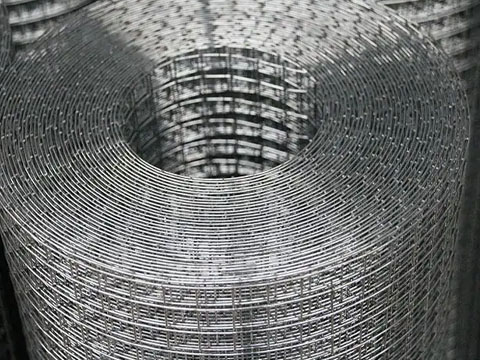

Galvanized steel wire mesh roll

| Wire Diameter | 0.3mm – 4.0mm |

| Mesh Size | 6.35mm (1/4″) – 50.8mm (2″) |

| Roll Width (Width) | 0.5m – 2.0m |

| Roll Length (Length) | 15m – 30m/roll |

| Galvanizing Type | Electrogalvanized / Hot-dip galvanized |

| Zinc Coating Weight | Electrogalvanized: 10-30g/m²; Hot-dip galvanized: ≥60g/m² |

| Processing | Welding, braiding |

Production Process for Laminated Pearlescent Film Metal Coil

There are generally two production processes for galvanized steel wire mesh: one involves welding followed by galvanizing, while the other employs galvanizing before welding. The first method offers superior protection, as both weld points and wires are fully encapsulated by the zinc coating. Below is a detailed description of the first production process:

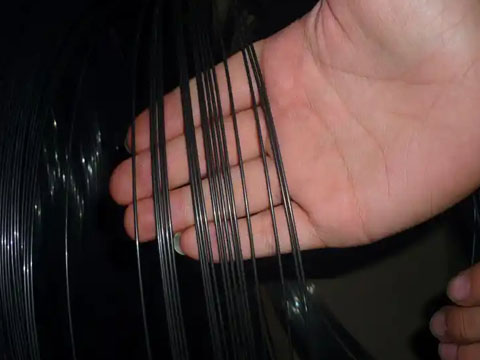

- Raw Material Selection and Pre-treatment: High-quality low-carbon steel wire rods are selected. The rods undergo acid washing, degreasing, and other treatments to remove surface oils and impurities.

- Wire Drawing and Welding: Pre-treated thick rods are drawn to precise wire diameters. Subsequently, large-scale fully automated welding machines perform resistance welding at the intersection points of longitudinal and transverse wires.

- Galvanizing and Cooling: After welding, the wire is immersed in an ammonium zinc chloride flux bath. Following fluxing, it undergoes hot-dip galvanizing or electrogalvanizing, then enters a cooling tank to solidify the zinc coating.

- Passivation: The cooled mesh may undergo passivation to form a protective film, further enhancing corrosion resistance.

- Quality Inspection: Rigorous testing of finished products, including zinc coating thickness measurement, weld tensile strength testing, mesh aperture size verification, and surface quality inspection.

- Packaging: Mesh panels are bundled or rolled according to customer specifications and prepared for shipment.

Advantages of Our Galvanized Wire Mesh

- Exceptional Durability: The galvanized coating provides robust protection, with hot-dip galvanized products lasting 15-20 years and electro-galvanized products lasting 5-10 years, effectively resisting corrosion in harsh environments.

- Structurally Sound and Reliable: Crafted from premium low-carbon steel wire using precision welding/weaving techniques, ensuring uniform mesh openings, secure joints, high tensile strength, and resistance to breakage.

- Flexible Customization for Wide Applications: Mesh size, wire diameter, and dimensions are fully customizable with high precision, precisely meeting diverse needs in construction, industry, aquaculture, and more.

- Safe and eco-friendly for worry-free use: Raw materials and production processes comply with environmental and safety standards, being non-toxic and harmless. Suitable for use in food processing, children’s activity areas, and other environments with stringent safety requirements.

Galvanized Steel Wire Mesh Applications

- Construction and Civil Engineering: Concrete reinforcement, slope protection, road protection, wall insulation reinforcement, floor heating pipe support, and drainage slope protection.

- Agriculture and Horticulture: Poultry cages, livestock fences, orchard fences, grape trellises, seedbed supports, and greenhouse frame support nets.

- Industrial Manufacturing: Protective mesh for machinery and equipment, warehouse shelving, and material filtration screens (for mining, chemical, and food applications).

- Home and Public Facility: Residential fences, sports field fencing, storage racks, and anti-theft door and window linings.

What Galvanized Iron Wire Mesh Do We Supply?

Galvanized iron wire mesh comes in various types. With our comprehensive supply chain, we can provide all kinds of galvanized iron wire mesh, including:

- Galvanized wire mesh sheets and galvanized wire meshrolls.

- Hot-dip galvanized wire mesh and electro-galvanized wire mesh.

- Woven galvanized wire mesh, welded galvanized wire mesh, and chain link galvanized wire mesh (diamond mesh).

Why Choose Us

- As a professional manufacturer of galvanized steel products, we maintain precise control over the supply chain for galvanized steel coils and related products.

- Our advanced production processes and equipment not only guarantee product quality but also enable us to manufacture a full range of sizes to meet the needs of diverse industries.

- We are ISO 9001 and ISO 14001 certified, and we supply reliably to over 100 countries worldwide.

If you have any questions regarding galvanized steel wire mesh, please feel free to contact us. Please note that we offer factory wholesale pricing, but we have a minimum order quantity requirement of 5 tons.

Related Products

Project Solutions

Agricultural Greenhouse

Highway Engineering

Metal Construction Products

- Metal Roofing

- Metal Sandwich Panel

- Metal Carved Panel

- Angle Steel

- Channel Steel

- Expandable Container House

- 40ft Double-Wing Expandable House

Wanzhi Hot Products

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China