Coated steel sheet specifications

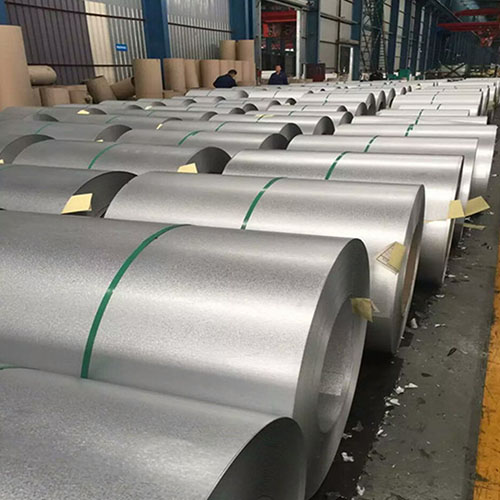

Wanzhi Steel Coated Steel Sheets include hot-dip galvanized steel, electro-galvanized steel, aluminum-zinc-coated steel, ZAM steel and other coated products.

Wanzhi Steel Factory is located in Boxing County, Binzhou City, Shandong Province, with an annual output of over 320,000 tons, producing coated steel plates of various specifications and colors. If you need to purchase coated steel, please contact Wanzhi. Please indicate the product specifications and quantity information when inquiring. View all Coated Steel products

Hot dip galvanized steel sheet specifications

Hot dip galvanized steel sheet size specifications

| Thickness /mm | 0.35、0.40、 0.45 | 0.50、0.55、0.60、 0.65、0.70 | 0.75、0.80 | 0.90、1.0 | 1.1、1.2 | 1.3、1.4、 1.5 |

| Repeated bending times | 8 | 7 | 6 | 5 | 4 | 3 |

| Bending test | d=0(180°angle) d=a(180°angle) | d=a(180°180° angle) | Bend 90° | |||

| Bend 90° | ||||||

| Width/mm×Length/mm | 710×1420、750×750、750×1500、750×1800、800×800、800×1200、800×1600、850× 1700、900×900、900×1800、800×2000、1000×2000 | |||||

| Grade | The chemical composition of Q195, Q215A and Q235A complies with the requirements of GB/T700 | |||||

Note: The weight of zinc layer is 275g/㎡

Hot dip galvanized steel sheet theoretical weight table

| Thickness /mm | Width/mm×Length/mm | |||||||||||

| 710× 1420 | 750× 750 | 750× 1500 | 750× 1800 | 800× 800 | 800× 1200 | 800× 1600 | 850× 1700 | 900× 900 | 900× 1800 | 900× 2000 | 1000× 2000 | |

| Theoretical mass/(kg/sheet)(density:7.85) | ||||||||||||

| 0.35 | 2.77 | 1.54 | 3.09 | 3.71 | 1.76 | 2.64 | 3.52 | 3.97 | 2.22 | 4.45 | 4.94 | |

| 0.4 | 3.16 | 1.77 | 3.53 | 4.24 | 2.01 | 3.01 | 4.02 | 4.54 | 2. 54 | 5.09 | 5.65 | |

| 0.45 | 3.56 | 1.99 | 3.97 | 4.77 | 2.26 | 3.39 | 4.52 | 5.1 | 2.86 | 5.72 | 6.36 | |

| 0.5 | 3.96 | 2.21 | 4.42 | 5.3 | 2.51 | 3.77 | 5.02 | 5.67 | 3.18 | 6.36 | 7.06 | 7.85 |

| 0.55 | 4.35 | 2.43 | 4.86 | 5.83 | 2.76 | 4.14 | 5.52 | 6.24 | 3.5 | 6.99 | 7.77 | 8.64 |

| 0.6 | 4.75 | 2.65 | 5.3 | 6.36 | 3.01 | 4.52 | 6.02 | 6.8 | 3.81 | 7.63 | 8.48 | 9.42 |

| 0.65 | 5.14 | 2.87 | 5.74 | 6.89 | 3.27 | 4.9 | 6.53 | 7.37 | 4.13 | 8.27 | 9.18 | 10.2 |

| 0.7 | 5.54 | 3.09 | 6.18 | 7.42 | 3.52 | 5.28 | 7.04 | 7.94 | 4.45 | 8.9 | 9.89 | 10.99 |

| 0.75 | 5.94 | 3.31 | 6.62 | 7.95 | 3.77 | 5.65 | 7.54 | 8.51 | 4.77 | 9.54 | 10.6 | 11.78 |

| 0.8 | 6.33 | 3.53 | 7.07 | 8.48 | 4.02 | 6.03 | 8.04 | 9.07 | 5.09 | 10.17 | 11.3 | 12.56 |

| 0.9 | 7.12 | 3.97 | 7.95 | 9.53 | 4.52 | 6.78 | 9.04 | 10.21 | 5.72 | 11.44 | 12.72 | 14.13 |

| 1 | 7.91 | 4.42 | 8.83 | 10.6 | 5.02 | 7.54 | 10.04 | 11.34 | 6.36 | 12.72 | 14.13 | 15.7 |

| 1.1 | 8.71 | 4.86 | 9.71 | 11.66 | 5.53 | 8.29 | 11.04 | 12.47 | 6.99 | 13.99 | 15.54 | 17.27 |

| 1.2 | 9.5 | 5.3 | 10.6 | 12.72 | 6.03 | 9.04 | 12.04 | 13.61 | 7.63 | 15.26 | 16.96 | 19.84 |

| 1.3 | 10.29 | 5.74 | 11.48 | 13.78 | 6.53 | 9.8 | 13.06 | 14.74 | 8.27 | 16.53 | 18.37 | 20.41 |

| 1.4 | 10.08 | 6.18 | 12.36 | 14.84 | 7.03 | 10.55 | 14.08 | 15.88 | 8.9 | 17.8 | 19.78 | 21.98 |

| 1.5 | 11. 87 | 6.62 | 13.25 | 15.9 | 7.54 | 11.3 | 15.08 | 17.01 | 9.54 | 19.07 | 21.2 | 23.35 |

Performance classification and surface treatment classification

| Grade | Performance level code | Scope of application | Surface treatment | Symbols |

| General purpose | 1 | Passivation | C | |

| Mechanical bonding | 2 | The zinc layer quality code shall not exceed Z350 | Oiling | O |

| Stamping | 3 | Thickness range is ≥0.4mm and zinc layer quality shall not exceed Z275 | Paint seal | L |

| Deep drawing | 4 | Phosphate | P | |

| Special killed steel deep drawing | 5 | No treatment | U | |

| Non-aging ultra-deep drawing | 6 | |||

| Structural grade | 220、250、280、320、 350、400、450、550 | Steel plates with thickness < 0.4 mm Not applicable to grades 220, 250, 280 and 320 |

Grades and chemical compositions of hot-dip galvanized steel sheets and strips

| Performance Level | Chemical composition (mass fraction) (%) | ||||

| C | Mn | P | S | Ti | |

| 1 | 0.15 | 0.6 | 0.035 | 0.035 | |

| 2 | 0.12 | 0.6 | 0.035 | 0.035 | |

| 3 | 0.12 | 0.5 | 0.03 | 0.03 | |

| 4 | 0.1 | 0.45 | 0.025 | 0.025 | |

| 5 | 0.08 | 0.45 | 0. 020 | 0.02 | |

| 6 | 0.02 | 0.25 | 0.01 | 0.02 | 0.3 |

| Structural grade | 0.25 | 1.7 | 0.05 | 0.035 | |

Mechanical and process properties of 01~06 grade steel plates and strips

| Grade | Zinc layer | Yield strength /MPa | Tensile strength /MPa | Elongation after break/% | r90 | n90 | Steel base 180° cold bending diameter (d, horizontal) | |

| Plate thickness (a) | ||||||||

| ≤ | <3mm | ≥3mm | ||||||

| 1 | Z | – | – | – | – | – | 1a | 2a |

| ZF | ||||||||

| 2 | Z | – | 270~500 | 22 | – | – | 0 | 1a |

| ZF | ||||||||

| 3 | ZF | 140~300 | 270~420 | 26 | – | – | – | – |

| 4 | Z | 140~260 | 270~380 | 30 | – | – | – | – |

| ZF | ||||||||

| 5 | Z | 140~270 | 270~350 | 36 | 1.6 | 0.18 | – | – |

| ZF | 34 | 1.4 | ||||||

| 6 | Z | 120~280 | 270~ 350 | 39 | 1.9 | 0.21 | – | – |

| ZF | 37 | 1.7 | 0. 20 | |||||

Mechanical and process properties of structural grade steel plates

| Grade | Yield strength /MPa | Tensile strength /MPa | Elongation after break/% | Steel base 180° bending diameter (d, transverse) | |

| ≥ | ≥ | ≥ | Plate thickness (a) | ||

| <3mm | ≥3mm | ||||

| 220 | 220 | 300 | 20 | la | 2a |

| 250 | 250 | 330 | 19 | la | 2a |

| 280 | 280 | 360 | 18 | 2a | 3a |

| 320 | 320 | 390 | 17 | 3a | 3a |

| 350 | 350 | 420 | 16 | ||

| 400 | 400 | 470 | – | 3a | 3a |

| 500 | 500 | 530 | – | ||

| 550 | 550 | 560 | – | – | – |

Hot dip galvanized steel sheet zinc layer quality

| Coating Type | Coating code | Double-sided three-point detection Minimum average value/(g/m2) | Single point detection minimum value/(g/㎡) | |

| Double-sided | Single-sided | |||

| Zinc | (Z60) | (60) | (51) | (24) |

| Z80 | 80 | 68 | 32 | |

| Z100 | 100 | 85 | 40 | |

| Z120 | 120 | 102 | 48 | |

| Z150 | 150 | 128 | 60 | |

| Z180 | 180 | 153 | 72 | |

| Z200 | 200 | 170 | 80 | |

| Z220 | 220 | 187 | 88 | |

| Z250 | 250 | 213 | 100 | |

| Z275 | 275 | 234 | 110 | |

| Z350 | 350 | 298 | 140 | |

| Z450 | 450 | 383 | 180 | |

| Z600 | 600 | 510 | 240 | |

| Zinc-iron alloy | (ZF40) | (40) | (34) | (16) |

| ZF60 | 60 | 51 | 24 | |

| ZF80 | 80 | 68 | 32 | |

| ZF100 | 100 | 85 | 40 | |

| ZF120 | 120 | 102 | 48 | |

| ZF150 | 150 | 128 | 60 | |

| (ZF180) | (180) | (153) | (72) | |

Hot-dip galvanized aluminum steel sheet specifications

Classification and code of hot-dip galvanized steel sheet

| Classification by surface quality | Grade | Code | Coating type, coating surface structure, surface treatment classification and code | Item | Classification | Code | ||

| Ordinary surface | FA | Surface treatment | Complex acid passivation | C | ||||

| No glutinous passivation | C5 | |||||||

| Higher-end surfaces | FE | Oiling | O | |||||

| Coating type, coating surface structure, surface treatment classification and code | Item | Classification | Code | Chromic acid passivation + oiling | CO | |||

| Chromium-free passivation + oiling | CO5 | |||||||

| Coating Type | Aluminum-zinc alloy coating | AZ | Anti-fingerprint film | AF | ||||

| Coating surface structure | Ordinary zinc spangle | N | Chrome-free anti-fingerprint film | AF5 | ||||

| No treatment | U | |||||||

Hot dipped aluminum zinc steel plate grades and steel type characteristics

| Grade | Steel grade characteristics | Grade | Steel grade characteristics |

| DX51D+AZ | Mild steel or interstitial free steel | S280GD+AZ | Structural Steel |

| DX52D+AZ | S300GD+AZ | ||

| DX53D+AZ | S320GD+AZ | ||

| DX54D+AZ | S350GD+AZ | ||

| S250GD+AZ | Structural Steel | S550GD+AZ0 |

Chemical composition of hot-dip aluminum-zinc steel plate

| Grade | Chemical composition (melting analysis) (mass fraction) /% ≤ | |||||

| C | Si | Mn | P | S | Ti | |

| DX51D+AZ | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 |

| DX52D+AZ | ||||||

| DX53D+AZ | ||||||

| DX54D+AZ | ||||||

| S250GD+AZ | 0. 20 | 0.6 | 1.7 | 0.1 | 0.045 | |

| S280GD+AZ | ||||||

| S300GD+AZ | ||||||

| S320GD+AZ | ||||||

| S350GD+AZ | ||||||

| S550GD+AZ | ||||||

Mechanical properties of hot-dip aluminum-zinc steel plate

| Grade | Tensile test | ||

| Yield strength /MPa | Tensile strength /MPa | Elongation after break/% | |

| DX51D+AZ | 500 | 22 | |

| DX52D+AZ | 300 | 420 | 26 |

| DX53D+AZ | 260 | 380 | 30 |

| DX54D+AZ | 220 | 350 | 36 |

| S250GD+AZ | 250 | 330 | 19 |

| S280GD+AZ | 280 | 360 | 18 |

| S300GD+AZ | 300 | 380 | 17 |

| S320GD+AZ | 320 | 390 | 17 |

| S350GD+AZ | 350 | 420 | 16 |

| S550GD+AZ | 550 | 560 | |

Recommended coating quality of hot-dip aluminum-zinc

| Coating Type | Coating form | Recommended nominal coating mass/(g/㎡) | Coating code |

| Hot-dip aluminum-zinc alloy coating (AZ) | Equal thickness coating | 60 | 60 |

| 80 | 80 | ||

| 100 | 100 | ||

| 120 | 120 | ||

| 150 | 150 | ||

| 180 | 180 | ||

| 200 | 200 |

Equivalent grades of hot-dip aluminum-zinc steel sheet

| GB/T 14978-2008 | AS | EN 10326:2004 | ASTM | JIS | ISO |

| 1397-2001 | EN 10327:2004 | A792M-06a | G 3321:2005 | 9364:2001 | |

| DX51D+AZ | DX51D+AZ | CS type B、type C | SGLCC | 1 | |

| DX52D+AZ | G2+AZ | DX52D+AZ | FS | SGLCD | 2 |

| DX53D+AZ | G3+AZ | DX53D+AZ | DS | 3 | |

| DX54D+AZ | DX54D+AZ | EDDS | |||

| S250GD+AZ | G250+AZ | S250GD+AZ | Grade 255 | 250 | |

| S280GD+AZ | S280GD+AZ | Grade 275 | 280 | ||

| S300GD+AZ | G300+AZ | SGLC400 | |||

| S320GD+AZ | S320GD+AZ | SGLC440 | 320 | ||

| S350GD+AZ | G350+AZ | S350GD+AZ | Grade 345 Class 1 | 350 | |

| S550GD+AZ | G550+AZ | S550GD+AZ | Grade 550 Class 1 | SGLC570 | 550 |

Specifications of color-coated steel sheet

Size range of color coated sheets

| Item | Nominal size | Item | Nominal size |

| Thickness/mm | 0.20-2.0 | Steel plate length | 1000~6000 |

| Width/mm×Length/mm | 600-1600 | Inner diameter of steel coil | 450、508 or 610 |

Classification and codes of color-coated sheets

| Classification | Item | Code | Classification | Item | Code |

| According to use | Building exterior | JW | Classified by coating surface state | Embossed board | YA |

| Building interior | JN | Printed board | YI | ||

| Home appliances | JD | Classified by topcoat type | Polyester | PE | |

| Others | QT | Silicon-modified polyester | SMP | ||

| By substrate type | Hot-dip galvanized substrate | Z | High-durability polyester | HDP | |

| Hot-dip galvanized iron alloy substrate | ZF | Polyvinylidene fluoride | PVDF | ||

| Hot-dip aluminum-zinc alloy substrate | AZ | Classified by coating structure | Two layers on the front and one layer on the back | 2/1 | |

| Hot-dip galvanized aluminum alloy substrate | ZA | Two layers on the front and two layers on the back | 2/2 | ||

| Electro-galvanized substrate | ZE | Classified by hot-dip galvanized substrate surface structure | Polishing small zinc flowers | MS | |

| According to the coating surface state | Coated sheet | TC | Finishing without zinc flower | FS |

Grands and uses of color-coated sheets

| Color coated steel plate grades | Use | ||||

| Hot dip galvanized substrate | Hot dip galvanized iron alloy substrate | Hot dip aluminum zinc alloy substrate | Hot dip galvanized aluminum alloy substrate | Electrogalvanized substrate | |

| TDC51D+Z | TDC51D+ZF | TDC51D+ AZ | TDC51D+ZA | TDCO1+ZE | General use |

| TDC52D+Z | TDC52D+ZF | TDC52D+AZ | TDC52D+ZA | TDCO3+ZE | Stamping |

| TDC53D+Z | TDC53D+ZF | TDC53D+AZ | TDC53D+ZA | TDC04+ZE | Deep stamping |

| TDC54D+Z | TDC54D+ZF | TDC54D+ AZ | TDC54D+ZA | – | Extra deep stamping |

| TS250GD+Z | TS250GD+ZF | TS250GD+AZ | TS250GD+ZA | – | Structural use |

| TS280GD+Z | TS280GD+ZF | TS280GD+AZ | TS280GD+ZA | – | |

| TS300GD+AZ | – | ||||

| TS320GD+Z | TS320GD+ZF | TS320GD+AZ | TS320GD+ZA | – | |

| TS350GD+Z | TS350GD+ZF | TS350GD+AZ | TS350GD+ZA | – | |

| TS5S0GD+Z | TS550GD+ZF | TSSS0GD+AZ | TS550GD+ZA | – | |

Mechanical properties of hot dip galvanized substrate and color coated sheet

| Grade | Yield strength /MPa | Tensile strength /MPa | Elongation after break(L。=80mm,b=20mmm)/% ≥ | |

| Nominal thickness/mm | ||||

| ≤0.7 | >0.70 | |||

| TDC51D+Z、TDC51D+ZF、TDC51D+ AZ、TDC51D+ZA | 270~500 | 20 | 22 | |

| TDC52D+Z、TDC52D+ZF、TDC52D+ AZ、TDC52D+ZA | 140~300 | 270~420 | 24 | 26 |

| TDC53D+Z、TDC53D+ZF、TDC53D+ -AZ、TDC53D+ZA | 140~260 | 270~380 | 28 | 30 |

| TDC54D+Z、TDC54D+AZ、TDC54D+ ZA | 140~220 | 270~350 | 34 | 36 |

| TDC54D+ZF | 140~220 | 270~350 | 32 | 34 |

| TS250GD+Z、TS250GD+ZF、TS250GD+ AZ、TS250GD+ZA | 250 | 330 | 17 | 19 |

| TS280GD+Z、TS280GD+ZF、TS280GD+ AZ、TS280GD+ZA | 280 | 360 | 16 | 18 |

| TS300GD+AZ | 300 | 380 | 16 | 18 |

| TS320GD+Z、TS320GD+ZF、TS320GD+ AZ、TS320GD+ZA | 320 | 390 | 15 | 17 |

| TS350GD+Z、TS350GD+ZF、TS350GD+ AZ、TS350GD+ZA | 350 | 420 | 14 | 16 |

| TS550GD+Z、TS550GD+ZF、TS550GD+ AZ、TS550GD+ZA | 550 | 560 | – | – |

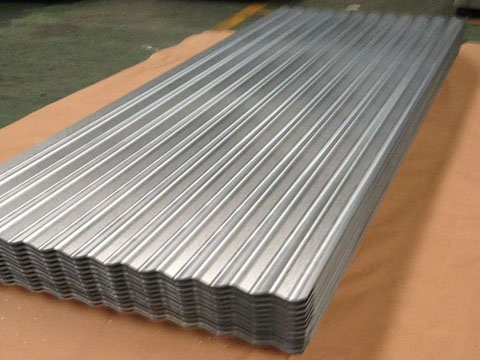

conclusion

Coated steel is a kind of steel with strong corrosion resistance but competitive price. It is widely used and suitable for a variety of commercial buildings and industrial applications. At Wanzhi Steel, we can provide coated steel products suitable for your application. You can refer to the above table to find the coated steel specifications you need and leave us a message to send inquiry information.

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China

Product Recommendations

Color coated steel

- PPGI STEEL COIL

- CORRUGATED STEEL SHEETS

- PPGL

- PATTERN PPGI

- PREPAINTED STEEL SHEETS

- PPGI FOR WRITING BOARDS

- PPGI FOR FENCE

- PPGI FOR HOME APPLIANCES

- PREPAINTED ALUMINUM COIL

- MATT TEXTURED PPGI

- COLOUR COATED ROOFING SHEET

Roofing Sheet

Stainless Steel

Other Coil & Sheet

- COLD ROLLED COILS

- HOT ROLLED STEEL

- EMBOSSED STEEL

- METAL CARVED PANEL

- COLD ROLLED STEEL SHEET

- PERFORATED SHEET METAL

- Q235 STEEL

Industry dynamics

- Uruguay Procures 150 Tons of RAL7024 Color-Coated Steel Coils

- Nigeria Procures 300 Tons of PPGL Corrugated Steel Sheets

- UAE Procures 100 Tons of PPGI Strips

- Belarusian Customer Procures 124 tons Stainless Steel Strip for Steel Pipe Production

- Brazilian Client Purchases 52 Tons of DX51D+AZ30 GL Steel Coils