Coated steel sheet

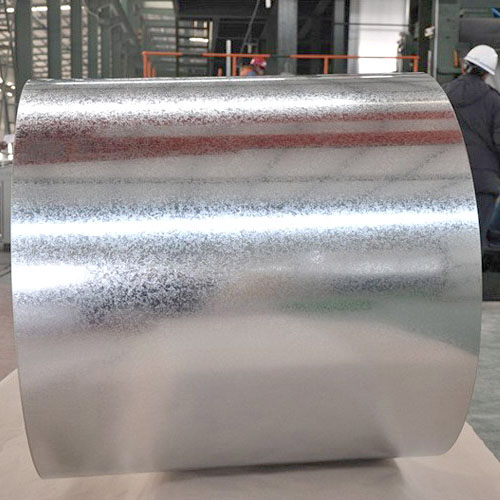

Wanzhi Steel has 3 coating production lines, which can provide various coated steel coils and steel plates to meet customers’ different applications.

Table of Contents

Coated steel sheet specifications

| Product Name | Coated Steel |

| Thickness(mm) | 0.12 – 4mm |

| Width(mm) | 600 – 2000mm |

| Length(mm) | 1000 – 6000mm or as your request |

| Grade | SGCC,SGCH,G550,DX51D,DX52D,DX53D,DC01,DC02 |

| Zinc Coating(g/㎡) | 30 – 275 g/㎡ |

| Spangle Type | Large zinc flower, ordinary zinc flower, small zinc flower, zero zinc flower |

| Coating Type | Z, ZE, AZ, ZA, ZF |

| Processing Services | Profile processing, shearing, cutting, etc. |

| Standard | AISI、ASTM、BS、GB、JIS |

| MOQ | 10 tons |

| Packing | Standard export package or as per your requirements |

| Payment Terms | EXW, FOB, CIF, CFR etc. |

| Delivery Time | 15-25 working days after payment |

Chemical composition of different materials

| Material | Chemical composition (mass fraction)/%, not more than | |||||

| C | Si | Mn | P | S | Ti | |

| DX51D+Z, DX51D+ZF, DX51D+ZA, DX51D+AZ | 0.18 | 0.5 | 1.2 | 0.12 | 0.045 | 0.3 |

| DX52D+Z, DX52D+ZF, DX52D+ZA, DX52D+AZ | 0.12 | 0.6 | 0.1 | |||

| DX53D+Z, DX53D+ZF, DX53D+ZA, DX53D+AZ | ||||||

| DX54D+Z, DX54D+ZF, DX54D+ZA, DX54D+AZ | ||||||

| DX56D+Z, DX56D+ZF, DX56D+ZA, DX56D+AZ | ||||||

| DX57D+Z, DX57D+ZF, DX57D+ZA, DX57D+AZ | ||||||

| Material | Chemical composition (mass fraction)/%, not more than | ||||

| C | Si | Mn | P | S | |

| S220GD+Z,S220GD+ZF,S220GD+ZA.S220GD+AZ | 0.2 | 0.6 | 1.7 | 0.1 | 0.045 |

| S250GD+Z.S250GD+ZF,S250GD+ZA.S250GD+AZ | |||||

| S280GD+Z.S280GD+ZF,S280GD+ZA.S280GD+AZ | |||||

| S300GD+Z.S300GD+ZF,S300GD+ZA,S300GD+AZ | |||||

| S320GD+Z.S320GD+ZF,S20GD+ZA.S320GD+AZ | |||||

| S350GD+Z,S350GD+ZF,S350GD+ZA,S350GD+AZ | |||||

| S390GD+Z,S390GD+ZF,S390GD+ZA,S390GD+AZ | |||||

| S420GD+Z.S420GD+ZF.S420GD+ZA.S420GD+AZ | |||||

| S450GD+Z.S450GD+ZF.S450GD+ZA.S450GD+AZ | |||||

| S550GD+Z,S550GD+ZF,S550GD+ZA,S550GD+AZ | |||||

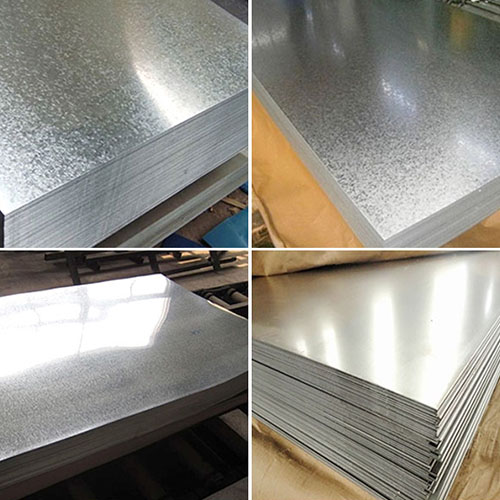

Coated steel products

The coated steel sheet products provided by our factory include galvanized steel sheet, galvalume steel sheet, electro-galvanized steel sheet, hot-dip galvanized steel sheet, galvanized roof sheet, color-coated roof sheet, hot-dip galvalume steel, DX51D steel, ZAM Steel, etc.

Thicknesses: 0.12mm-4mm

Width: 600mm-2000mm

Zinc Coating: 30-275g/m²

Thickness: 0.12-1.2 mm

Width: 600-1,250 mm

Al-Zn Coating: AZ30-150

Thicknesses:0.3mm-2mm

Width:600mm-1,500mm

Zinc Coating: 10-30 g/m²

Thickness: 0.12-4.0mm

Width: 600-1500mm

Zinc Coating: 30-275g/㎡

Thickness: 0.15-2.0mm

Width: 600-1250mm or customizable

Zinc Coating: 40-275g/m2

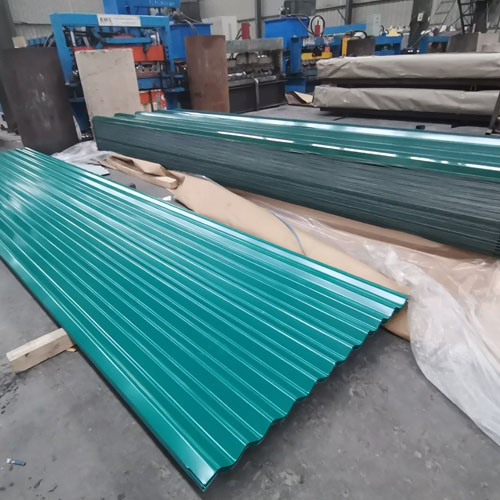

Thickness: 0.12-2.0mm

Width: 40-1250mm

Color: Ral Color Code or customer sample

Wanzhi coated steel plate substrate types

Wanzhi coated steel plate substrate types include: hot-dip galvanized substrate (Z), electro-galvanized substrate (ZE), hot-dip aluminum-zinc alloy substrate (AZ), hot-dip galvanized aluminum alloy substrate (ZA), hot-dip galvanized iron alloy substrate (ZF). The following table shows the recommended coating weights in different corrosion environments and different substrates.

| Substrate type | Nominal coating weight (g/m2) | ||

| Corrosive environment | |||

| Low | Medium | High | |

| Hot dip galvanized substrate (Z) | 90/90 | 125/125 | 140/140 |

| Electrogalvanized substrate (ZE) | 40/40 | 60/60 | ~ |

| Hot-dip aluminum-zinc alloy substrate (AZ) | 50/50 | 60/60 | 75/75 |

| Hot-dip galvanized aluminum alloy substrate (ZA) | 65/65 | 90/90 | 110/110 |

| Hot-dip galvanized iron alloy substrate (ZF) | 60/60 | 75/75 | 90/90 |

Application of coated steel sheets

- Application of hot-dip galvanized steel sheet: used in construction, packaging, vehicles, agricultural machinery, chemicals, textiles and daily necessities.

- Application of hot-dip aluminum-zinc alloy coated steel: mainly used in construction, home appliances, electronic appliances and automobiles.

- Application of color coated steel: generally used in construction, light industry, automobiles, electrical appliances, and other industries; also used in agricultural machinery, furniture and daily necessities.

- Application of electrogalvanized coated steel: generally used in automobiles, electronics, home appliances and other industries.

Characteristics and uses of different zinc flowers

| Surface morphology type | Quality characteristics | Application |

| Small zinc flower | Because the crystal growth of zinc spangles is controlled, the surface grain structure is fine; because the surface is uniform, the surface quality after painting is excellent; the paintability is better than conventional zinc spangles. | Various containers, home appliances, electrical equipment housings, etc. that need to be further painted; and as the base material for coated steel sheets. |

| Zero spangle | Because the growth of zinc particles is completely controlled during the solidification process of molten zinc, it is difficult to see zinc flowers with the naked eye; because the surface is uniform, the surface quality after painting is excellent. | The main use is in the automotive industry; and as a base material for coated steel sheets. |

| Finishing zinc flower | After the molten zinc solidifies, it is leveled to obtain an extremely smooth surface; because the surface is smooth, the surface quality after painting is excellent. | In addition to being the base material for coated steel sheets, it has more advanced uses than small zinc flowers. |

Packaging and storage

Wanzhi coated steel packaging

Wanzhi packaging adopts vertical packaging plus wooden pallet for coated steel coils, and wooden pallet for coated steel sheets. If you have special requirements for packaging, we can also meet your requirements.

Coated steel storage recommendations

- It is recommended to store it indoors and avoid outdoor storage; the indoor environment should be dry and ventilated without corrosive gases.

- If it is necessary to store it outdoors, it is necessary to place square sleepers under the steel as pads, choose a flat ground, and the top of the pads should be level so that the steel is on the same horizontal line. Finally, it is necessary to cover it with a rainproof cloth to prevent the steel from being directly exposed to the sun and rain.

- The steel coil should be stored as much as possible in the state it left the factory, and do not pile it up to avoid damaging the coating.

- The steel should be stored in a clean and tidy environment to avoid erosion by various corrosive media.

- Color coated steel plates should not be placed in places with a lot of sand and dust. Because if there is sand and dust on the steel plate, it may damage the coating.

FAQ about Coated steel sheet

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China

Product Recommendations

Color coated steel

- PPGI STEEL COIL

- CORRUGATED STEEL SHEETS

- PPGL

- PATTERN PPGI

- PREPAINTED STEEL SHEETS

- PPGI FOR WRITING BOARDS

- PPGI FOR FENCE

- PPGI FOR HOME APPLIANCES

- PREPAINTED ALUMINUM COIL

- MATT TEXTURED PPGI

- COLOUR COATED ROOFING SHEET

Roofing Sheet

Stainless Steel

Other Coil & Sheet

- COLD ROLLED COILS

- HOT ROLLED STEEL

- EMBOSSED STEEL

- METAL CARVED PANEL

- COLD ROLLED STEEL SHEET

- PERFORATED SHEET METAL

- Q235 STEEL

Industry dynamics

- Uruguay Procures 150 Tons of RAL7024 Color-Coated Steel Coils

- Nigeria Procures 300 Tons of PPGL Corrugated Steel Sheets

- UAE Procures 100 Tons of PPGI Strips

- Belarusian Customer Procures 124 tons Stainless Steel Strip for Steel Pipe Production

- Brazilian Client Purchases 52 Tons of DX51D+AZ30 GL Steel Coils